3D Printing Transforms Industrial Design

How 3D Printing is Reshaping Design and Manufacturing

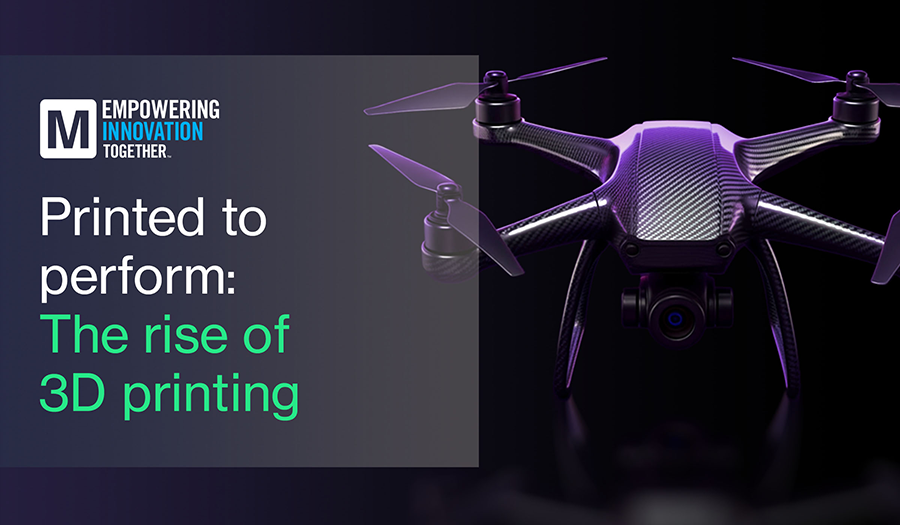

Mouser Electronics has launched a new installment of its Empowering Innovation Together series. Titled “That’s 3D Printed?”, it explores how additive manufacturing is transforming industrial processes through advanced materials and artificial intelligence.

The Evolution of Additive Manufacturing

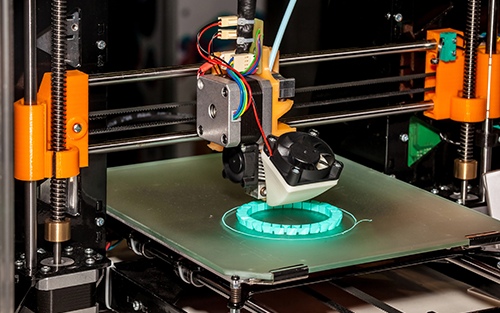

3D printing has evolved beyond basic prototyping into a sophisticated manufacturing technology. Its core strength lies in creating complex geometries and internal structures impossible with traditional methods. Recent advancements in AI and novel materials have dramatically expanded its applications. These range from FAA-approved titanium engine components to biocompatible medical implants.

Expert Insights on Manufacturing Transformation

Mouser’s “The Tech Between Us” podcast features industry leaders discussing additive manufacturing’s impact. Mark Beatty, CEO of 3D Agility, explains how the technology is altering equipment lifecycles and obsolescence strategies. Meanwhile, Stefanie Brickwede of Mobility goes Additive details the progression of materials and applications in European manufacturing.

Engineering Freedom and Supply Chain Solutions

Raymond Yin, Mouser Director of Technical Content, emphasizes the technology’s accelerating impact. “Additive manufacturing isn’t new, but its impact is accelerating,” Yin notes. “With novel materials and AI, engineers can now design with greater precision and fewer limitations.” This creative flexibility enables engineers to solve real-world supply chain challenges through fast, on-demand production.

Author’s Perspective: The Industrial Automation Shift

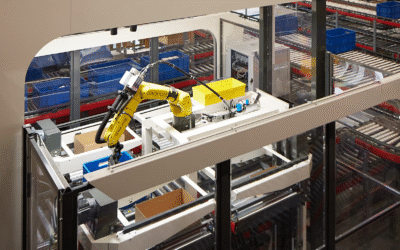

3D printing represents more than just a manufacturing alternative—it’s fundamentally changing design philosophy. Engineers are no longer constrained by traditional manufacturing limitations. This enables optimized designs that improve performance while reducing material usage. For industrial automation, this means faster prototyping, customized tooling, and on-demand spare parts production.

The integration of AI further enhances this transformation. Machine learning algorithms can now optimize designs for specific performance criteria while ensuring manufacturability. This synergy between AI and additive manufacturing creates new possibilities for complex automation components and systems.

Practical Applications for Industrial Automation

Customized Tooling and Fixtures

Manufacturers can rapidly produce specialized jigs, fixtures, and tooling adapted to specific production lines, reducing lead times from weeks to days.

On-Demand Spare Parts

Industrial facilities can maintain digital inventories and 3D print replacement parts as needed, minimizing downtime and reducing physical storage requirements.

Optimized Component Design

Engineers can create lightweight, complex components with internal cooling channels or customized mounting features impossible with subtractive manufacturing.

Comprehensive Educational Resources

The EIT series provides extensive technical content beyond the podcast. Engineers can access in-depth videos, technical articles, and detailed infographics. The content covers new materials, AI tools, and engineering workflow changes. This educational initiative helps professionals develop innovative solutions for on-demand production and customized manufacturing.

Frequently Asked Questions

What makes modern 3D printing different from earlier versions?

Current systems integrate AI optimization, advanced materials including metals and biomaterials, and production-level speed and precision.

How does 3D printing benefit supply chain management?

It enables localized production, reduces inventory needs, and allows rapid response to part obsolescence or emergency requirements.

What industries are adopting additive manufacturing?

Aerospace, medical, automotive, and industrial automation are leading adoption, with applications expanding across all manufacturing sectors.

Can 3D printed parts meet industrial quality standards?

Yes, many applications now achieve certification for critical components, including FAA-approved aircraft parts and medical implants.

Where can engineers learn more about industrial 3D printing applications?

Mouser’s Empowering Innovation Together series provides comprehensive technical resources, case studies, and expert interviews.

About Mouser Electronics

Mouser Electronics is an authorized distributor of semiconductors and electronic components, serving the global engineering community with over 6.8 million products from 1,200 manufacturer brands. The company’s educational initiatives, including the Empowering Innovation Together program launched in 2015, provide valuable technical resources for design engineers worldwide.

LEAVE A COMMENT