A Guide to Industrial Communication Protocols

What Is an Industrial Communication Protocol?

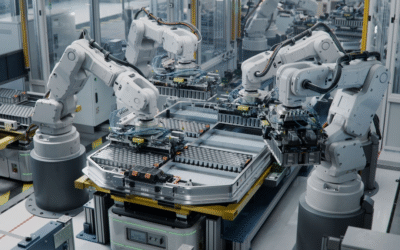

The Common Language of Factory Devices

An industrial communication protocol is a defined set of rules. It allows different devices to talk to each other. Think of it as a common language for machines. Without it, a PLC could not understand a sensor. This framework ensures reliable and structured data exchange.

Why Standardized Protocols Are Essential

Factories use equipment from many different vendors. A Siemens PLC might need data from an Allen-Bradley drive. Standardized protocols make this interoperability possible. They eliminate communication barriers between brands. Consequently, they provide engineers with great flexibility.

The Core Function: Data Exchange and Control

Protocols fundamentally serve two key purposes. First, they move data from field devices to controllers. This data includes sensor readings and valve positions. Second, they transmit control commands from the controller back to the devices.

Contrasting Traditional Serial and Modern Ethernet Protocols

Early protocols like Modbus RTU used serial communication. They were simple but slow. Modern systems now favor Ethernet-based protocols. Examples include Profinet and Ethernet/IP. These protocols offer much higher speed and more data.

Exploring Key Protocol Examples

Several major protocols dominate the industry. Profinet is common in European manufacturing. Ethernet/IP is widely used in North America. Modbus TCP remains a popular, simple choice. OPC UA is now the standard for IIoT and cloud connectivity.

How Protocols Ensure Data Integrity

These rules define how to package a message. They include source and destination addresses. They also add error-checking information. The receiving device then checks this information. This process guarantees the data’s accuracy.

The Critical Role in System Integration

Protocols are the backbone of system integration. They connect the shop floor to the top floor. A sensor can send data directly to a supervisory system. This enables real-time monitoring and data-driven decision making.

Choosing the Right Protocol for Your Application

Your choice depends on several factors. Consider the required speed and data volume. Also, evaluate the existing equipment vendor ecosystem. Furthermore, think about future IIoT and analytics needs. There is no one-size-fits-all solution.

Real-World Scenario: A Simple Conveyor System

A photoeye sensor detects a box using a discrete protocol. A motor drive controls the conveyor speed via an analog signal. A PLC coordinates everything using a network protocol like Ethernet/IP. This seamless communication keeps the system running smoothly.

The Future with OPC UA and IIoT

OPC UA is becoming the universal translator for industry. It provides a secure, vendor-neutral information model. Moreover, it enables seamless data flow from PLCs to enterprise cloud systems. This is a key enabler for the Industrial Internet of Things (IIoT).

Frequently Asked Questions (FAQ)

Q1: Can different protocols communicate with each other?

Not directly. They need a gateway device. A gateway acts as a translator. It converts messages from one protocol to another, enabling communication.

Q2: What is the difference between Ethernet/IP and Profinet?

Both use standard Ethernet hardware. However, their application layers are different and incompatible. Ethernet/IP uses the CIP protocol, while Profinet uses its own standard.

Q3: Is Modbus still relevant today?

Yes, absolutely. Modbus TCP is very widely deployed. Its simplicity and openness make it a popular choice for connecting basic devices and systems.

Q4: Why are proprietary protocols still used?

Vendors sometimes use them to lock customers into their ecosystem. However, the strong industry trend is moving towards open, standard protocols like OPC UA.

Q5: What skills do engineers need for these protocols?

You need to understand network fundamentals. Knowing how to configure IP addresses is crucial. Experience with specific protocol configuration software is also highly valuable.

LEAVE A COMMENT