ABB and LKAB Mining Technology Partnership

Strategic Partnership Advances Mining Industry Digital Transformation

Collaborative Framework Establishment

ABB and Swedish mining leader LKAB have formalized a strategic technology partnership. This memorandum of understanding creates a collaborative framework for mining innovation. The alliance focuses on automation, electrification, and digitalization solutions for mineral extraction operations.

Technology Development Focus Areas

The partnership targets critical mining industry transformation requirements. Key development areas include advanced energy systems and production management solutions. Moreover, the collaboration will explore robotic applications for hazardous mining operations.

Energy System Innovations

The companies will develop smarter power distribution and storage technologies. Battery-electric vehicle charging infrastructure represents another priority area. These innovations aim to reduce mining operations’ environmental footprint significantly.

Production Optimization Strategies

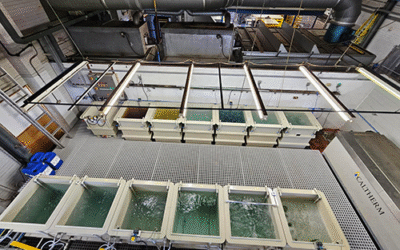

The collaboration encompasses entire mining value chain improvements. Ventilation, milling, and flotation processes will receive particular attention. Consequently, these enhancements should increase operational efficiency while reducing energy consumption.

Robotic Application Exploration

Potential robotic developments include automated blast charging systems. The partnership will also investigate safer hoisting solutions for deeper mining operations. Such technologies could dramatically improve worker safety in hazardous environments.

Industry Leadership Perspective

“We face one of mining’s most significant technology shifts,” stated Jenny Greberg, LKAB’s Technology VP. “Combining our mining expertise with ABB’s technological leadership will establish new industry benchmarks for safety and sustainability.”

Market Research Validation

Recent ABB research indicates strong industry support for technological transformation. Seventy-seven percent of mining executives consider automation and digitalization essential for sustainable operations. This partnership directly addresses these recognized industry needs.

Implementation Governance Structure

A joint steering committee with representatives from both organizations will guide the collaboration. This governance approach ensures strategic alignment and effective project execution. Senior leadership from both companies will oversee initiative progress.

Expert Analysis: Mining Technology Evolution

This partnership represents a significant step in mining’s technological evolution. Traditional extraction methods increasingly give way to digitalized, automated operations. Such collaborations accelerate industry-wide adoption of sustainable mining practices.

Implementation Scenario: Electric Vehicle Integration

Consider underground mining operations transitioning to battery-electric vehicles. The partnership could develop smart charging systems that optimize energy usage across shifts. This approach would reduce diesel emissions while maintaining operational productivity.

Frequently Asked Questions

What specific technologies will this partnership develop?

The collaboration focuses on energy management, production optimization, and robotic applications. These include BEV charging, automated blast systems, and digital production management platforms.

How will this partnership benefit the broader mining industry?

Successful technology implementations will establish industry benchmarks. Other mining companies can adopt proven solutions to accelerate their own digital transformations.

What timeframe governs this collaboration?

The memorandum establishes a long-term framework without fixed expiration. This allows for extended technology development and implementation cycles typical in mining.

How does this align with sustainability objectives?

Electrification and automation directly reduce mining’s environmental impact. Digital optimization decreases energy consumption while improving operational efficiency.

What role will robotics play in future mining operations?

Robotics will increasingly handle hazardous tasks like blast charging and deep-haulage operations. This improves safety while enabling operations in challenging environments.

Strategic Importance

This partnership demonstrates how industry leaders can collaboratively address complex challenges. The combination of mining expertise and technology innovation creates powerful transformation catalysts. Such alliances will likely become increasingly common across resource industries.

About ABB

ABB is a global technology leader in electrification and automation solutions. The company enables sustainable and resource-efficient operations across industrial sectors. With 140 years of industry experience, ABB employs approximately 110,000 professionals worldwide.

About ABB’s Process Automation

ABB’s Process Automation business provides comprehensive automation solutions for industrial operations. The division serves process, hybrid and maritime industries with advanced technologies and digital expertise.

LEAVE A COMMENT