ABB Gearless Mill Drive Service for Codelco Mines

ABB Strengthens Mining Operations with Advanced Gearless Mill Drive Service for Codelco

Strategic Partnership for Enhanced Mining Performance

SANTIAGO, Chile, Sept. 2, 2025 – ABB has solidified a significant new collaboration with Codelco, Chile’s state-owned copper mining corporation. This long-term service agreement focuses on optimizing maintenance operations for critical grinding mill systems. Moreover, this partnership supports Chile’s position as the world’s leading copper producer. The comprehensive program includes maintenance services, remote diagnostic capabilities, and specialized technical training. Consequently, these services will enhance gearless mill drive system performance across multiple mining sites.

Integrated Service Management Across Mining Operations

Under this agreement, ABB will manage the complete lifecycle of four major GMD installations. Three systems operate at the Ministro Hales mine in Antofagasta, while one serves the Andina mine in Valparaíso. Although these facilities span over 1,500 kilometers and feature different designs, ABB will implement centralized service management. Therefore, this approach ensures consistent operational standards and performance optimization. The program specifically targets improved equipment reliability and reduced environmental impact through advanced technology solutions.

Sustainable Mining Technology Advancements

Gearless mill drives represent crucial technology for modern copper processing plants. These systems enable efficient ore grinding while significantly reducing energy consumption and emissions. As global copper demand continues growing, maintaining reliable grinding operations becomes increasingly vital. This service agreement directly supports Codelco’s operational objectives by maximizing equipment availability and preventing unexpected downtime. Furthermore, it demonstrates how industrial automation can drive both productivity and sustainability in mining.

Industry Expertise Driving Operational Excellence

Francisco Herrera, Service Manager for ABB’s Process Industries division in Chile, emphasized the partnership’s significance. “Our collaboration with Codelco spans more than ten years. This new contract allows us to expand our support using specialized expertise and digital technologies,” Herrera stated. “Both companies remain committed to implementing innovative solutions within Chilean mining operations. This commitment ensures production targets are met efficiently and sustainably.”

Technical Innovation in Mineral Processing

ABB’s gearless mill drive technology eliminates traditional mechanical transmission components. These systems power the world’s largest grinding mills, essential infrastructure for mineral extraction. By removing intermediate gears and related components, GMDs deliver superior operational efficiency and reliability. Additionally, they contribute to lower emissions, supporting the mining industry’s transition toward more sustainable practices. As global electrification accelerates, maximizing output of critical minerals becomes increasingly important for decarbonization efforts.

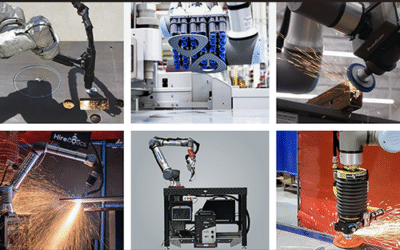

Application Scenario: Mining Automation Solutions

Industrial automation systems like ABB’s GMD Connect platform demonstrate how digital transformation benefits mining operations. The cloud-based monitoring system enables predictive maintenance, reducing unplanned downtime by up to 25% in similar applications. Remote diagnostics allow technical experts to identify potential issues before they cause operational disruptions. Furthermore, integrated training programs ensure mine personnel maintain proficiency with evolving technology. This comprehensive approach represents the future of industrial automation in resource extraction.

Industry Perspective: The Future of Mining Automation

The mining sector increasingly adopts industrial automation technologies to address operational challenges. Gearless mill drives exemplify how advanced control systems enhance both productivity and sustainability. As copper demand grows for renewable energy infrastructure, efficient processing technology becomes crucial. Companies integrating comprehensive service agreements demonstrate forward-thinking operational strategies. Therefore, we anticipate increased adoption of similar automation maintenance programs across the mining industry.

About ABB

ABB stands as a global technology leader in electrification and automation solutions. The company enables sustainable and resource-efficient futures for industrial operations. With over 140 years of innovation history, ABB combines engineering excellence with digital expertise. Consequently, industrial clients achieve higher performance while improving efficiency and sustainability. The company employs more than 110,000 professionals worldwide and maintains listings on both SIX Swiss Exchange and Nasdaq Stockholm.

About ABB’s Process Automation Business

ABB’s Process Automation division delivers comprehensive solutions for industrial operations. The business automates, electrifies, and digitalizes essential processes across multiple sectors. These include energy production, water management, and material processing industries. With approximately 20,000 employees worldwide, ABB Process Automation helps industrial clients achieve leaner and cleaner operations through advanced technology implementation.

Frequently Asked Questions

What are gearless mill drives in mining operations?

Gearless mill drives are advanced motor systems that directly power grinding mills without mechanical transmission components. They offer superior efficiency and reliability for mineral processing operations.

How does this agreement benefit Codelco’s mining operations?

The service agreement ensures optimized performance of critical grinding equipment through proactive maintenance, remote monitoring, and specialized technical support, thereby maximizing operational uptime.

What is the significance of remote diagnostics in mining automation?

Remote diagnostics enable continuous equipment monitoring and early problem detection. This approach prevents unexpected failures and reduces maintenance costs through predictive maintenance strategies.

How does mining automation support sustainability goals?

Automation technologies like GMDs reduce energy consumption and emissions while maintaining production output. They represent crucial solutions for environmentally responsible mineral extraction.

Why is copper production increasingly important?

Copper serves as essential material for electrification and renewable energy technologies. Growing demand requires efficient production methods to support global decarbonization efforts.

LEAVE A COMMENT