ABB Pulp Mill Optimization Software

ABB Revolutionizes Pulp Production with Advanced Industrial Automation Software

Transforming Pulp Mill Operations Through Digital Innovation

ABB has launched its groundbreaking Plant Optimizer for Pulp Mills solution. This dynamic software platform helps pulp manufacturers connect production planning with real-time operational control. Specifically engineered for the complex nature of pulp manufacturing, this technology enhances traceability while maintaining operational stability and reducing production expenses.

Addressing Modern Industrial Automation Challenges

Managing a pulp mill requires constant balancing of interconnected processes. Operators must maintain harmony across dozens of systems while handling unexpected disruptions and changing market demands. However, with many systems operating independently and experienced professionals retiring, maintaining visibility and responding quickly to problems has become increasingly difficult. This industrial automation solution provides real-time insights and decision support to help teams identify issues sooner and adjust operations more effectively.

Leveraging Decades of Process Automation Expertise

ABB brings extensive experience in pulp and paper industry automation to this new solution. The company has partnered with producers for decades, delivering tailored automation and digital solutions. Plant Optimizer for Pulp Mills represents the latest innovation in ABB’s industrial automation portfolio, addressing core operational challenges through three key capabilities: comprehensive traceability, economic optimization, and operational resilience.

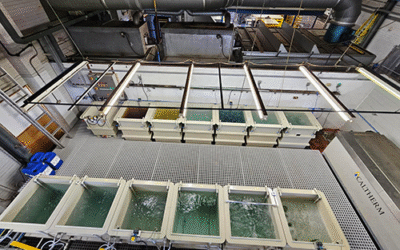

Enhancing End-to-End Process Control Systems

In pulp production, minor process deviations can create significant ripple effects throughout operations. This software provides operators and engineers with enhanced visibility and tools for faster decision-making. By tracking material flows and quality variables in real-time, manufacturers can identify inefficiencies more quickly and trace quality issues to their source. The system’s automated grade transitions and diagnostic features help standardize operations and improve overall discipline in process control systems.

Dynamic Decision Support for Factory Automation

The software enables proactive rather than reactive planning through advanced decision support capabilities. It utilizes Manufacturing Execution System targets to develop weekly and daily production plans that consider actual operational constraints. By modeling different scenarios for demand fluctuations or bottleneck resolution, the system provides recommendations that balance throughput, cost, and resource utilization. This allows mills to optimize set-points and production rates continuously, minimizing waste while increasing output from existing assets.

Expert Perspective on Digital Transformation

“Digitalization extends beyond mere data access—it’s about converting operational complexity into clear, coordinated action,” stated Sanjit Shewale, global division head of Digital at ABB’s Process Industries division. “Plant Optimizer for Pulp Mills unifies planning and operations, enabling mills to operate more efficiently today while preparing for future autonomous operations.”

Expanding ABB’s Industrial Automation Portfolio

This new application strengthens ABB’s comprehensive suite of digital solutions for the pulp and paper sector. The company continues its commitment to helping producers maximize value from existing assets while navigating energy transitions and workforce challenges. As industrial automation evolves, such solutions become increasingly vital for maintaining competitive advantage in process industries.

Application Scenario: Real-World Implementation

Consider a pulp mill facing frequent production disruptions and quality variations. By implementing Plant Optimizer for Pulp Mills, the facility gains real-time visibility across its entire operation. The system automatically detects deviations in chemical pulp processing and recommends corrective actions before quality issues affect final product. During raw material changes, the software calculates optimal transition parameters, reducing waste and maintaining consistent output quality. This results in a 5-7% reduction in operational costs and improved response time to market changes.

Industry Trend Analysis

The pulp and paper industry increasingly adopts integrated control systems to address workforce transitions and efficiency demands. Modern DCS and PLC platforms now incorporate AI-driven optimization tools that learn from operational patterns. ABB’s latest offering aligns with this trend toward unified operational platforms that bridge traditional gaps between planning and execution systems. As industrial automation becomes more sophisticated, we expect to see greater emphasis on predictive optimization and autonomous decision-support features.

About ABB

ABB stands as a global technology leader in electrification and automation, driving sustainable and resource-efficient solutions. The company combines engineering excellence with digital expertise to help industries achieve superior performance, efficiency, and sustainability. With over 140 years of industry presence and approximately 110,000 employees worldwide, ABB continues to pioneer innovations that help clients outperform in their markets.

About ABB’s Process Automation Business

ABB’s Process Automation division delivers automation, electrification, and digital solutions for industrial operations spanning essential sectors. From supplying energy and materials to producing and transporting goods, the business unit helps process industries operate more efficiently and sustainably. With approximately 20,000 employees and leading technology expertise, ABB Process Automation enables leaner and cleaner industrial operations worldwide.

Frequently Asked Questions

What specific pulp production challenges does this software address?

The software tackles interconnected process management, quality consistency, and operational efficiency challenges. It helps mills maintain stability despite raw material variations and equipment disruptions while optimizing resource utilization across the production chain.

How does this solution integrate with existing control systems?

Plant Optimizer for Pulp Mills connects with existing DCS, PLC, and MES platforms through standard industrial communication protocols. This allows seamless data exchange while leveraging current automation investments.

What measurable benefits can mills expect from implementation?

Typical results include 3-5% higher throughput, 5-7% lower production costs, 15-20% faster response to process deviations, and significant reduction in quality-related waste.

Does this software require extensive operator training?

While the system features advanced capabilities, ABB designed it with intuitive interfaces that build upon operators’ existing knowledge. Comprehensive training and support ensure smooth adoption.

How does this solution support sustainability goals?

By optimizing resource consumption, reducing waste, and improving energy efficiency, the software helps mills lower their environmental impact while maintaining production targets.

LEAVE A COMMENT