ADMARES Uses Siemens Tech for Sustainable Housing

ADMARES Revolutionizes Home Construction with Siemens Digital Twin Technology

ADMARES partners with Siemens to transform housing construction through digitalization. The company utilizes Siemens Xcelerator platform to industrialize home manufacturing. This approach applies advanced digital twin and automation technologies. Consequently, ADMARES delivers sustainable, affordable housing at unprecedented speeds.

Addressing Global Housing Challenges

ADMARES tackles the worldwide housing shortage through industrialization. Traditional construction faces labor shortages and inefficiency. The company’s automated factory approach eliminates these constraints. Moreover, it reduces environmental impact significantly. This innovation makes quality housing more accessible globally.

Siemens Xcelerator Platform Implementation

The Siemens Xcelerator portfolio enables complete digital transformation. ADMARES uses Designcenter for modular housing design. Teamcenter manages product lifecycle data. Simcenter validates designs through simulation. These tools create a comprehensive digital twin. Therefore, the company optimizes both product and manufacturing process.

Environmental Impact Reduction

The automated approach delivers substantial sustainability benefits. ADMARES targets 75% reduction in CO₂ emissions. Material waste decreases by 80% compared to traditional methods. These achievements support global climate goals. Furthermore, they demonstrate green manufacturing’s commercial viability.

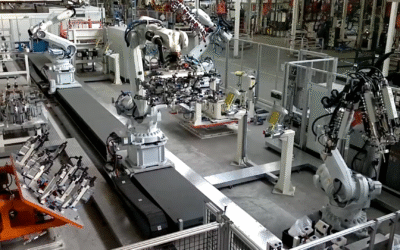

Manufacturing Efficiency Breakthrough

Siemens automation enables remarkable production speeds. The smart factory achieves 22.5-minute takt time per building unit. Complete 1,400 square foot homes are produced in 45 minutes. Opcenter manufacturing software coordinates all operations. This efficiency revolutionizes housing delivery timelines.

Leadership Perspectives

“Siemens technology makes homes a product, not a labor-dependent process,” stated Mikael Hedberg, ADMARES CEO. “We can automate manufacturing to deliver affordable homes at needed scale and speed.”

“ADMARES exemplifies how Siemens enables new business models,” said Eryn Devola, Siemens Sustainability Head. “They’ve transformed housing into a scalable, digitalized product using our digital twin and automation technologies.”

Smart Home Integration

Manufactured homes include advanced monitoring capabilities. Built-in software tracks energy consumption patterns. Water usage and air quality are monitored in real-time. These features create fully connected smart homes. Residents benefit from optimized living environments and reduced utility costs.

Industry Transformation Potential

This partnership demonstrates construction industry digitalization. Traditional methods are replaced by automated manufacturing. Digital twins enable continuous optimization. The approach is scalable across global markets. Therefore, it represents a viable solution to housing crises.

Frequently Asked Questions

What production rate does ADMARES achieve?

The factory produces a complete 1,400 square foot home every 45 minutes using automated processes.

How does this reduce environmental impact?

The system cuts CO₂ emissions by 75% and reduces material waste by 80% compared to conventional construction.

Which Siemens software is utilized?

ADMARES uses Designcenter, Teamcenter, Simcenter, and Opcenter from the Siemens Xcelerator portfolio.

What are the housing units equipped with?

Homes include monitoring systems for energy, water, and air quality, making them smart connected residences.

How does this address labor shortages?

Automated manufacturing reduces dependence on skilled construction labor, enabling scalable production despite workforce limitations.

LEAVE A COMMENT