Advanced MES for Semiconductor Manufacturing

Critical Manufacturing Debuts Advanced MES Platform at SEMICON West 2025

Company showcases integrated MES and AI-powered image analytics for semiconductor manufacturing excellence

Industry Event Participation Announcement

September 17, 2025 – Critical Manufacturing prepares for its inaugural appearance at SEMICON West 2025, scheduled for October 7-9 in Phoenix, Arizona. The leading Manufacturing Execution System provider will demonstrate how its integrated platform delivers crucial insights for high-precision semiconductor production. The company’s solutions address mounting industry pressures including advanced chip fabrication demands and complex global supply chain challenges.

Comprehensive Manufacturing Execution Capabilities

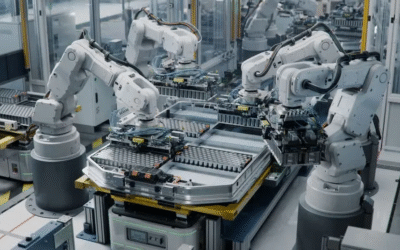

Critical Manufacturing MES provides complete production visibility and comprehensive end-to-end traceability. The system enables real-time monitoring throughout wafer and die processing stages. Advanced run-to-run control maintains process stability while allowing precise recipe adjustments for individual chambers. Seamless integration with wafer sorting equipment ensures smooth material movement across fabrication facilities. The combined IoT Data Platform delivers contextualized information instantly, enabling rapid response to production changes and variability minimization.

AI-Powered Image Analytics Integration

The company will feature c-Alice, an artificial intelligence image analysis solution from recent acquisition Convanit. This specialized technology serves critical inspection applications in high-tech manufacturing environments. c-Alice performs real-time image analysis for defect detection and classification while directly linking results to MES workflows. By combining visual intelligence with live process data, engineers gain comprehensive quality visibility during active production. This integration supports rapid, informed decision-making for maintaining high yields in demanding semiconductor operations.

Executive Perspective on Manufacturing Challenges

Jeff Peabody, Vice President of Sales & Business Development at Critical Manufacturing, emphasizes the event’s significance. “SEMICON West provides exceptional opportunities for direct manufacturer engagement about critical shop floor concerns. We want visitors departing our booth to understand how much simpler material tracing, data utilization, and quality control become with integrated platform solutions. Our MES combined with c-Alice delivers enhanced insights for managing complex processes in this rapidly accelerating industry.”

Event Participation and Demonstration Opportunities

Critical Manufacturing will sponsor the Smart Manufacturing Pavilion at booth SM2. Attendees can schedule personalized demonstrations and expert consultations showcasing integrated MES, data platform, and c-Alice functionality. The company offers complimentary one-day passes for qualified manufacturing professionals seeking smarter, more efficient production solutions.

Professional Analysis: The Evolving Semiconductor Manufacturing Landscape

The semiconductor industry faces unprecedented challenges requiring advanced digital manufacturing solutions. Critical Manufacturing’s approach demonstrates how integrated MES platforms combined with AI analytics create competitive advantages. For semiconductor manufacturers, this means moving beyond traditional statistical process control toward real-time, data-driven decision making. The integration of visual inspection data with production execution systems represents particularly significant advancement, enabling immediate correlation between visual defects and process parameters. This capability becomes increasingly crucial as chip geometries shrink and quality requirements intensify across automotive, medical, and aerospace applications.

Application Scenario: Semiconductor Fab Yield Optimization

Challenge: Leading semiconductor manufacturer experiences yield variations in advanced node production without clear correlation between process parameters and visual defects.

Solution: Implementation of Critical Manufacturing MES with integrated c-Alice AI image analytics for real-time defect classification and process correlation.

Outcome: 15% yield improvement through immediate defect source identification, 30% reduction in engineering analysis time, and enhanced process control through real-time visual and parametric data integration.

About Critical Manufacturing

Critical Manufacturing maintains leadership recognition in the Gartner Magic Quadrant as an ASMPT subsidiary. The company delivers modern, flexible manufacturing execution systems with extensive configurability. Their MES solutions help manufacturers exceed stringent traceability and compliance requirements while reducing risks through inherent closed-loop quality systems. Seamless integration with enterprise systems and factory automation provides deep intelligence and global production visibility. Consequently, customers achieve Industry 4.0 readiness while effectively competing through adaptable operations responsive to demand fluctuations and evolving requirements.

About ASMPT Corporate Structure

ASMPT operates as a premier global provider of semiconductor and electronics manufacturing hardware and software solutions. The Singapore-headquartered company serves semiconductor assembly, packaging, and surface mount technology markets. Their comprehensive offerings span from wafer deposition to sophisticated electronic component organization, assembly, and packaging solutions. These technologies enable diverse end-user devices across electronics, mobile communications, computing, automotive, industrial, and display sectors. ASMPT maintains close customer partnerships with continuous research and development investments, delivering cost-effective, industry-shaping solutions for enhanced productivity, reliability, and quality.

Essential Manufacturing Technology Questions

How does Critical Manufacturing MES address semiconductor traceability requirements?

The system provides complete end-to-end traceability with real-time monitoring throughout wafer and die processing, ensuring compliance with stringent industry requirements.

What advantages does c-Alice provide for semiconductor inspection?

c-Alice delivers real-time AI-powered image analysis for defect detection and classification while directly linking visual results to MES workflows for immediate process correlation.

How does the integrated platform support semiconductor yield improvement?

By combining real-time process monitoring with visual defect analysis, engineers gain comprehensive production visibility for rapid decision-making and variability reduction.

What manufacturing challenges does the MES platform specifically address?

The system tackles advanced chip production complexities, supply chain challenges, process stability maintenance, and quality control in high-precision environments.

How does the solution support Industry 4.0 implementation?

Through integrated IoT data platforms, seamless automation connectivity, and AI-powered analytics, the system enables adaptive, data-driven manufacturing operations.

LEAVE A COMMENT