Advanced Tube Forming Automation Solutions

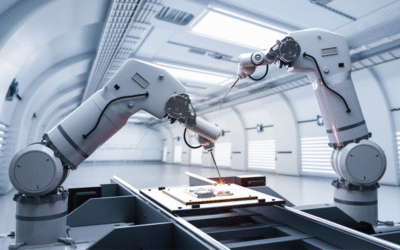

Revolutionizing Tube Forming with Robotic Automation at FABTECH 2025

Strategic Partnership Announcement

Wauseon Machine collaborates with Kawasaki Robotics to present innovative manufacturing solutions. Their joint exhibition at FABTECH 2025 showcases integrated automation systems for tube forming applications.

Event Details and Location

The demonstration takes place from September 8-11 at Chicago’s McCormick Place. Visitors can find the partners at booth B15001 in the main exhibition hall.

Advanced Manufacturing Solutions

The companies will demonstrate robotic tube forming systems for industrial automation. These solutions address complex production challenges in modern manufacturing environments.

High-Mix Production Capabilities

Their technology manages diverse production volumes efficiently. The system adapts to varying batch sizes while maintaining precision and quality standards.

Technical Expertise Integration

Kawasaki contributes industrial robotics knowledge to the partnership. Wauseon Machine adds four decades of tube forming experience and fabrication expertise.

Live Demonstration Features

Attendees will witness operational automation systems in real-time. The demonstration includes robotic handling and precision tube forming processes.

Business Growth Opportunities

Manufacturers can discover how these solutions improve operational efficiency. The technology helps companies expand their production capabilities significantly.

Company Background and History

Wauseon Machine began operations in 1983 as a small machine shop. Today, the company operates five manufacturing facilities across multiple states.

Technical Capabilities Overview

The organization combines engineering expertise with advanced equipment. They develop customized automation solutions for specific industrial requirements.

Industry Perspective and Analysis

From my experience in industrial automation, such partnerships demonstrate significant value. Integrated solutions typically reduce production costs by 15-25% while improving quality consistency.

Application Scenarios

Automotive manufacturers benefit from these tube forming systems for exhaust components. Aerospace companies use similar technology for hydraulic line production.

Implementation Considerations

Companies should evaluate their production volume requirements carefully. The technology works best for medium to high-volume manufacturing operations.

Frequently Asked Questions

What types of tube forming applications does this technology support?

The systems handle various metal forming applications including bending, cutting, and end forming operations for multiple industries.

How does robotic integration improve tube forming processes?

Robotic systems enhance precision and repeatability while reducing manual labor requirements and production cycle times.

What industries typically use these automation solutions?

Automotive, aerospace, furniture, and industrial equipment manufacturers are primary users of these advanced forming systems.

Can the systems handle different material types?

Yes, the technology processes various metals including steel, aluminum, and copper alloys with appropriate tooling adjustments.

What training requirements exist for operating these systems?

Operators typically need basic robotics programming knowledge and tube forming process understanding for optimal system utilization.

LEAVE A COMMENT