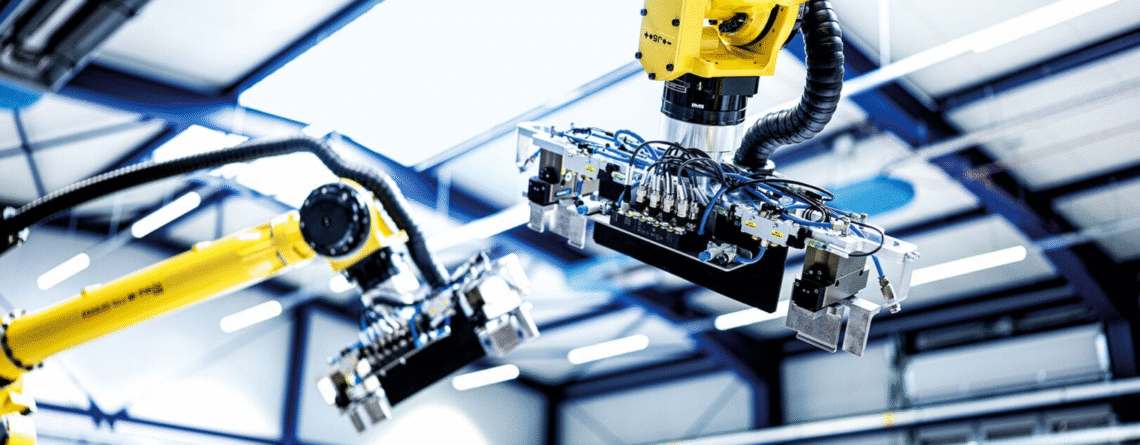

AI in Industrial Automation

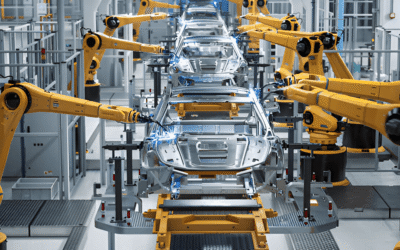

AI Transforms Industrial Automation: A New Era of Smart Factories

Artificial intelligence is revolutionizing industrial automation. It brings unprecedented intelligence to manufacturing systems. AI algorithms analyze vast amounts of operational data. Therefore, they enable smarter decision-making and autonomous operations.

Enhancing Predictive Maintenance Capabilities

AI-powered systems predict equipment failures accurately. They analyze vibration patterns and temperature data. Consequently, manufacturers can prevent unplanned downtime effectively. This approach saves millions in lost production.

Optimizing Production Quality Control

Computer vision systems now detect microscopic defects. They inspect products at incredible speeds. Moreover, they learn from each inspection cycle. This continuous improvement dramatically reduces quality issues.

Revolutionizing Supply Chain Management

AI algorithms forecast demand with remarkable precision. They analyze market trends and historical data. Additionally, they optimize inventory levels automatically. This results in significant cost savings.

Creating Autonomous Material Handling

Smart robots navigate factories independently. They use machine learning to optimize routes. Furthermore, they collaborate safely with human workers. This synergy enhances overall productivity.

Improving Energy Efficiency

AI systems monitor energy consumption patterns. They identify waste areas instantly. Then, they automatically adjust equipment settings. This intelligent management reduces carbon footprint.

Real-World Application: AI in Automotive Manufacturing

A major automaker implemented AI vision systems. These systems inspect weld quality in real-time. Previously, human inspectors missed subtle defects. Now, the system catches 99.9% of flaws immediately.

The Future of Human-Machine Collaboration

AI creates new roles for factory workers. It handles repetitive, dangerous tasks. Meanwhile, humans focus on complex problem-solving. This partnership yields the best results.

Frequently Asked Questions (FAQs)

How does AI improve manufacturing safety?

AI monitors workplace conditions continuously. It detects potential hazards before accidents occur. This proactive approach protects workers effectively.

What data do AI systems need for automation?

They require historical production data and real-time sensor readings. This combination enables accurate predictions and optimizations.

Can small manufacturers afford AI solutions?

Yes, cloud-based AI services are becoming affordable. They offer subscription models suitable for smaller operations.

How long does AI implementation typically take?

Most plants see initial results within three to six months. However, full optimization may take twelve to eighteen months.

Will AI replace all factory workers?

No, AI will transform job roles instead. It creates new positions in data analysis and system management.

LEAVE A COMMENT