Bently Nevada 3500 vs EPRO MMS Comparison

Bently Nevada 3500 vs. EPRO MMS: Which Condition Monitoring System Fits Better?

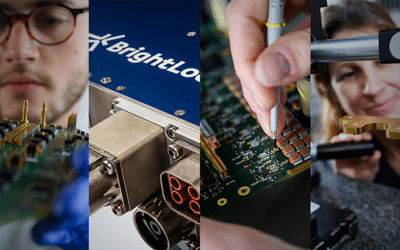

System Overview and Core Technology

Bently Nevada 3500 and EPRO MMS represent leading condition monitoring platforms for industrial machinery. The Bently Nevada system utilizes modular architecture with robust vibration monitoring capabilities. Meanwhile, EPRO MMS emphasizes comprehensive protection and advanced diagnostic features for critical equipment.

Vibration Monitoring Capabilities

Bently Nevada 3500 excels in high-frequency vibration analysis with superior dynamic range. The system provides detailed spectral data for early fault detection. Conversely, EPRO MMS offers reliable overall vibration measurement with strong transient capture abilities.

System Integration and Compatibility

The 3500 system integrates seamlessly with existing GE and third-party control systems. It supports multiple communication protocols including Modbus and Ethernet/IP. However, EPRO MMS demonstrates exceptional compatibility with Siemens automation environments and PROFIBUS networks.

Hardware Reliability and Durability

Bently Nevada hardware withstands extreme industrial environments with proven long-term reliability. The modular design facilitates easy maintenance and component replacement. Alternatively, EPRO modules provide robust performance in high-temperature applications with enhanced electrical isolation.

Software and Diagnostic Features

System 1 software from Bently Nevada delivers advanced analytics and machine learning capabilities. It enables predictive maintenance through sophisticated algorithm processing. EPRO’s PRISM software focuses on user-friendly interfaces and efficient data management for maintenance teams.

Installation and Maintenance Considerations

Bently Nevada installations require careful configuration but offer extensive customization options. Technical support availability varies by region but generally remains strong. EPRO systems feature straightforward installation procedures with comprehensive global service networks.

Cost Analysis and ROI

Initial investment for Bently Nevada 3500 typically exceeds EPRO MMS for equivalent configurations. However, the 3500 system may deliver better long-term value through extended asset life and reduced downtime. EPRO provides competitive pricing with excellent reliability for standard applications.

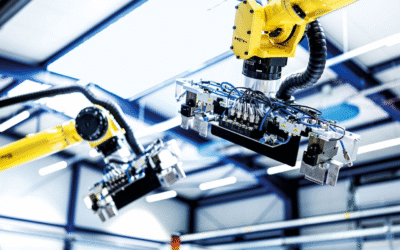

Industry-Specific Applications

Bently Nevada dominates the oil and gas sector with explosion-proof certifications and hazardous area compliance. The system excels in compressor and turbine monitoring applications. EPRO MMS demonstrates superior performance in power generation and industrial pump monitoring scenarios.

Expert Recommendation

From our condition monitoring experience, Bently Nevada 3500 suits operations requiring detailed vibration analysis and predictive capabilities. Choose EPRO MMS for reliable machinery protection with straightforward implementation. Consider existing infrastructure and technical expertise when selecting between these systems.

Implementation Best Practices

Conduct thorough machinery criticality assessment before system selection. Ensure proper sensor installation and calibration regardless of chosen platform. Develop comprehensive training programs for maintenance personnel. Establish clear documentation procedures for monitoring data and system configurations.

Frequently Asked Questions

Which system offers better vibration analysis?

Bently Nevada 3500 provides superior high-frequency analysis while EPRO MMS excels in overall vibration monitoring.

Are these systems compatible with existing DCS?

Both integrate with major DCS platforms, but compatibility varies depending on specific manufacturer protocols.

What’s the typical system lifespan?

Both systems offer 15-20 year operational lifespans with proper maintenance and component updates.

Which has better technical support?

Bently Nevada provides extensive global support, while EPRO offers strong regional service networks.

Can these systems monitor non-vibration parameters?

Yes, both platforms support temperature, pressure, and other process parameter monitoring.

LEAVE A COMMENT