Brushed DC Motors: Reliable Automation Solutions

Dunkermotoren GR Series brushed DC motors deliver reliable performance

Brushed DC Motors: Enduring Reliability in Modern Automation

Proven Performance in Critical Applications

Brushed DC motors maintain vital positions in motion technology. These components offer exceptional simplicity and reliability. Moreover, they provide cost-effective solutions for diverse applications. Dunkermotoren’s GR Series exemplifies these advantages. Consequently, engineers worldwide trust them for critical operations.

Why Reliability Matters in Automation

Industrial automation demands uncompromising reliability. Consider agricultural applications as examples. Planting and harvesting schedules allow no flexibility. Missed windows cause entire year losses. Therefore, motor failure becomes unacceptable. Dunkermotoren addresses this need effectively.

Key Advantages of Brushed DC Technology

Brushed motors offer distinct benefits over alternatives. Their simple construction ensures easy maintenance. Additionally, they require no complex controllers. Speed adjustment occurs through voltage variation. Furthermore, GR Series motors avoid rare earth materials. They often outperform BLDC motors regardless.

Technical Superiority in Demanding Environments

These motors deliver high starting torque consistently. This makes them ideal for frequent cycling applications. Door systems and power tools benefit particularly. They operate across wide voltage ranges too. Therefore, they adapt to various industrial environments seamlessly.

Robust Construction for Long Service Life

GR Series motors handle overload conditions effectively. They perform reliably in harsh environments. Proper protection ensures consistent operation. Moreover, they offer longer lifespans than competitors. Performance remains consistent across all production batches.

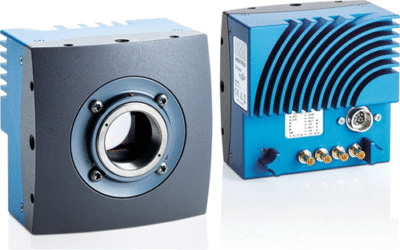

Modular Design Enhances Flexibility

The series supports extensive customization options. Engineers can integrate angular or planetary gearboxes. Encoders and brakes add functionality. This modularity represents a key differentiator. Consequently, solutions match specific application requirements perfectly.

Medical Technology Applications

Medical equipment demands precision and reliability. GR Series motors deliver smooth, quiet operation. They power portable and benchtop devices effectively. Pump applications benefit from consistent performance. Therefore, medical manufacturers choose them confidently.

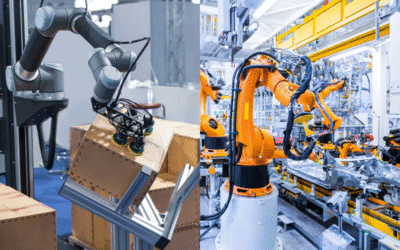

Building Automation Solutions

Automated door systems require dependable drives. Sliding, swing and revolving doors all use GR motors. Encoder and brake integration enhances functionality. Transportation applications include train steps and doors. Thus, building automation relies on their proven performance.

Industrial and Food Processing Uses

Factory automation needs robust motor solutions. Printers and processing systems utilize GR motors. Food automation requires specific protection levels. IP69K ratings ensure suitable performance. Agricultural equipment benefits from rugged designs.

Practical Implementation Example

Consider a packaging line automation project. The system requires reliable conveyor drives. Engineers need cost-effective motor solutions. Furthermore, they seek easy maintenance and high torque. GR Series brushed DC motors meet all requirements. Their simple control reduces system complexity. As a result, the packaging line achieves 99.2% uptime. Maintenance costs decrease by 35% annually.

Brushed DC motors continue evolving to meet modern demands. Dunkermotoren’s GR Series demonstrates this progression effectively. These components remain relevant in advanced automation systems. Therefore, engineers should consider them for reliable motion solutions.

LEAVE A COMMENT