Bulk Material Handling Drives

NORD DRIVESYSTEMS Powers Bulk Material Handling with Robust Drive Solutions

Customized drive systems deliver reliability in demanding bulk material handling applications across multiple industries

Tailored Solutions for Harsh Environments

Bulk material handling faces constant challenges from temperature shifts and abrasive conditions. NORD addresses these with modular drive systems specifically configured for each application. The company’s approach accommodates diverse plant arrangements and custom design requirements effectively.

High-Performance Stockyard Drive Systems

Stockyard systems serve as operational centers for bulk material handling. They provide essential storage and blending functions across multiple industries. NORD delivers durable drive solutions matched to material properties and operating conditions. The product range includes UNICASE helical bevel gear units and MAXXDRIVE industrial gear units. These integrate with NORDAC FLEX and NORDAC PRO frequency drives for optimal performance.

Reliable Conveyor System Applications

Conveyor systems form the backbone of bulk material transportation. They move aggregates, grains and powders throughout facilities. NORD engineers solutions for all conveyor types including horizontal and vertical configurations. MAXXDRIVE units handle large systems with torque capacities to 2.5 million lb-in. Smaller applications benefit from compact UNICASE gear units offering long service life.

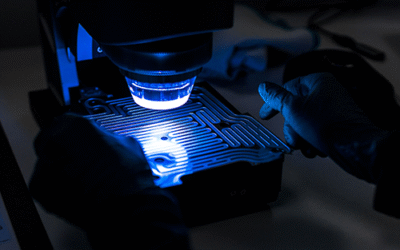

Precision Weighing and Metering Control

Accuracy becomes critical in weighing and dosing operations. NORD drives enable intelligent mass flow control through variable frequency drives. The POSICON integrated positioning mode ensures high precision metering. Plug-and-play capabilities simplify installation while integrated PLC functionality detects and resolves material blockages automatically.

Robust Loading and Unloading Equipment

Ports and processing plants require reliable high-torque solutions for material movement. NORD’s UNICASE gear units power demanding equipment like ship loaders and bucket-wheel stackers. These systems feature heavy-duty housings sealed against moisture and corrosion. Application-specific options include dust-protected brakes and continuous monitoring systems for enhanced durability.

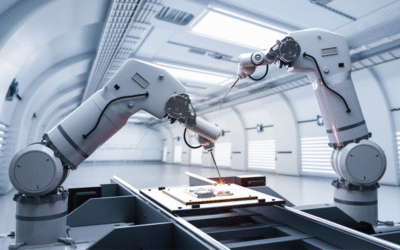

Technical Expertise and Global Support

NORD maintains continuous development of its extensive product portfolio. The company invests consistently in manufacturing and automation technology. With over 4,900 employees worldwide, NORD provides localized support through 80 countries. This global network ensures short delivery times and customer-oriented service for all drive system requirements.

Author’s Insight: The Engineering Behind Bulk Handling Reliability

NORD’s approach demonstrates how specialized drive engineering solves fundamental industrial challenges. The UNICASE housing technology represents more than just robust construction—it provides structural integrity that maintains gear alignment under extreme loads, directly impacting bearing life and system reliability. For plant engineers dealing with abrasive materials, the ability to specify exactly the right gear ratio and motor combination for each conveyor or stacker means avoiding both under-engineering (causing failures) and over-engineering (increasing costs). The integration of frequency drives with positioning control for metering applications shows how drive technology has evolved from simple power transmission to sophisticated process control elements.

Application Scenario: Port Terminal Conveyor System

Challenge: A port terminal needs to move 5,000 tons/hour of iron ore with minimal downtime in corrosive saltwater environment.

Solution: Implementation of NORD MAXXDRIVE gear units with corrosion-resistant coatings and NORDAC PRO frequency drives.

Outcome: The system achieves 99.2% availability with 40% reduction in maintenance costs and 15% energy savings through optimized drive control.

About NORD DRIVESYSTEMS

NORD DRIVESYSTEMS Group represents a global leader in drive technology solutions. With over 50 years of industry experience, the company delivers both standard and application-specific drive systems. The product range covers torque requirements from 88 lb-in to over 2.5 million lb-in. Power capabilities extend from 0.16 to 1,341 horsepower, serving diverse industrial applications worldwide.

Frequently Asked Questions (FAQs)

What industries benefit from NORD’s bulk handling solutions?

Mining, power generation, cement production, grain processing, and port operations all utilize NORD drive systems for reliable bulk material handling.

What torque ranges do NORD gear units cover?

NORD provides drive solutions from 88 lb-in to over 2.5 million lb-in, accommodating everything from small conveyors to massive stacker-reclaimers.

How do NORD drives enhance weighing accuracy?

Integrated POSICON positioning mode and synchronization in NORDAC frequency drives enable precise mass flow control for accurate weighing and metering.

What makes NORD drives suitable for harsh environments?

Heavy-duty housings, corrosion-resistant components, and specialized seals protect against moisture, dust, and abrasive conditions.

What control options are available for NORD drive systems?

Solutions range from conventional control cabinet installations to decentralized, fully-integrated drive units with integrated PLC functionality.

LEAVE A COMMENT