Chemical Etching for Energy Technology Manufacturing

Chemical Etching Powers Cross-Industry Energy Innovation

Precision Manufacturing for Clean Energy Systems

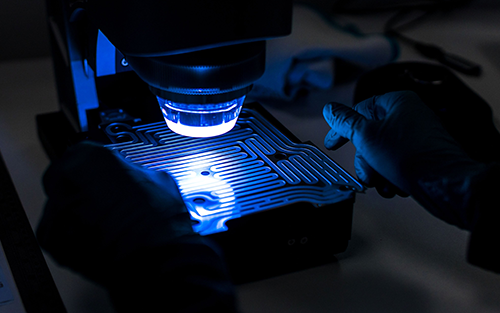

Chemical etching enables advanced energy technologies across multiple sectors. This manufacturing process uses controlled chemical reactions to shape metal components. It produces complex, stress-free parts that traditional methods cannot achieve. The technique supports innovations in space, aerospace, and transportation industries.

Space Technology Applications

Increasing space missions drive demand for specialized components. Chemical etching creates thin nickel interconnects for satellite batteries. These parts must withstand extreme deep-space conditions. The process maintains precision while allowing rapid design modifications. This flexibility proves crucial for missions like the Mars Rover and ExoMars.

Aerospace Thermal Management

Aircraft manufacturers focus on improving engine efficiency. Etched aluminum plates manage thermal performance in engines and fuel cells. These components have evolved over the past decade. Current manufacturing capabilities enable further optimization for next-generation aircraft. The technology supports both conventional and hydrogen-powered systems.

Ground Transportation Evolution

Electric and hydrogen vehicles represent complementary solutions. Hydrogen fuel cells show particular promise for heavy transport. Both technologies require precise etched components. Busbars, chaotic plates, and heat exchangers rely on chemical etching. The manufacturing process adapts easily from traditional automotive to new energy systems.

Autonomous Vehicle Integration

Self-driving vehicles incorporate etched copper busbars in battery systems. These components feature safety breakpoints to prevent full system failures. Chemical etching supports moderate-volume production during development phases. The technology enables quick adjustments to evolving design specifications. This flexibility proves invaluable during prototyping and testing.

Cross-Sector Technology Convergence

Energy system development follows similar patterns across industries. Clean power requirements drive innovation in multiple sectors. Chemical etching supports rapid prototyping and precision manufacturing. The process works with various materials including nickel, copper, and specialized alloys. This adaptability makes it essential for modern energy engineering.

Manufacturing Advantages

Chemical etching offers significant benefits over alternative methods. It eliminates mechanical stress and burrs from finished components. Tooling costs remain low while accommodating design changes. The process handles complex geometries with consistent accuracy. These characteristics make it ideal for precision energy components.

Industry Implementation Timeline

Automated vehicle technology will expand following 2027 regulations. Aerospace applications continue evolving toward cleaner propulsion. Space exploration demands increasingly sophisticated components. Chemical etching supports all these developments through adaptable manufacturing. The technology bridges prototyping and full-scale production phases.

Author’s Perspective: Manufacturing’s Strategic Role

Advanced manufacturing processes enable clean energy transitions. Chemical etching represents a critical enabling technology. Its precision and flexibility support rapid innovation cycles. Manufacturers who master this process gain significant competitive advantages. The technology demonstrates how production methods can drive sustainability.

Implementation Considerations

Companies should evaluate chemical etching for complex component production. The process suits moderate volumes and evolving designs. Material compatibility and precision requirements determine suitability. Manufacturers can transition from prototyping to production seamlessly. This approach reduces development time and costs.

Frequently Asked Questions

What industries use chemical etching?

Space technology, aerospace, electric vehicles, hydrogen systems, and autonomous vehicles all utilize chemical etching for precision components.

How does chemical etching benefit manufacturing?

It enables stress-free, burr-free components with complex geometries, low tooling costs, and rapid design modifications.

What materials work with chemical etching?

The process handles various metals including nickel, copper, aluminum, and specialized alloys for different applications.

Why is chemical etching important for energy systems?

It produces precise components for batteries, fuel cells, and thermal management systems across multiple energy technologies.

How does etching support product development?

The flexibility allows quick design changes during prototyping while maintaining precision for critical components.

LEAVE A COMMENT