Coriolis Flowmeter Market Growth 2025

Coriolis Flowmeters Maintain Market Leadership Through Continuous Innovation

Market Expansion and Growth Projections

Recent analysis from Flow Research reveals sustained growth in the Coriolis flowmeter sector. According to their latest market study, the global Coriolis flowmeter market reached $1.9 billion in 2024. Industry projections indicate this will surpass $2.4 billion by 2029. The market demonstrates a healthy 6.2 percent compound annual growth rate throughout the forecast period.

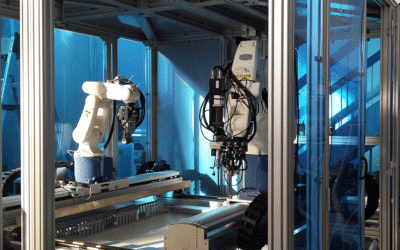

Technological Advancements Driving Performance

Manufacturers continue enhancing Coriolis meter capabilities through multiple approaches. Modern units achieve unprecedented accuracy levels while integrated diagnostic software enables continuous performance monitoring. This technology helps predict recalibration needs proactively. Straight tube designs, available in single and dual configurations, effectively resolve clogging issues common with bent tube models. Their compact construction facilitates installation in confined spaces while minimizing straight run requirements.

Expanding Application Range Across Industries

Coriolis technology now serves applications across the size spectrum. Larger models (6-16 inches) handle petroleum liquids and natural gas custody transfer despite their substantial size and weight. Conversely, miniature 1/16-inch meters manage chemical injection processes in pipelines. These compact units also serve pharmaceutical batching, food ingredient measurement, and specialty chemical applications. Laboratory-grade versions as small as 1/32-inch exist, though their delicate nature requires careful handling.

Competitive Positioning in Key Markets

Within the 2-to-4-inch pipe size range, Coriolis meters compete directly with ultrasonic and turbine technologies. Their APA-11 certification for natural gas fiscal metering makes them particularly valuable for precision measurement applications. These meters excel in natural gas feed systems for boilers, furnaces, and turbines. Additionally, they serve CNG and LNG distribution networks where accuracy at fluctuating flowrates proves critical. The density measurement capability provides additional value in these applications.

Lifecycle Cost Advantages Over Competing Technologies

The total cost of ownership analysis strongly favors Coriolis technology. Although initial purchase prices exceed many alternatives, reduced maintenance requirements create long-term savings. Unlike turbine and positive displacement meters, Coriolis designs contain no moving parts beyond the vibrating tube. This construction eliminates wear issues common with orifice plates. As companies streamline engineering teams, minimal maintenance requirements become increasingly valuable, delivering accumulating savings over time.

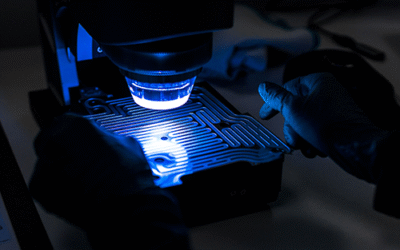

Material Science Breakthroughs Enhancing Durability

Recent material innovations significantly improve meter longevity and performance. Titanium construction reduces weight while increasing strength. New sensor tube materials like super duplex stainless steel provide superior resistance to pitting corrosion. These advancements enable reliable measurement of corrosive fluids that previously compromised accuracy through internal erosion. Consequently, applications expand into more challenging process environments.

Industry Expert Perspective

Dr. Jesse Yoder, President of Flow Research, emphasizes the technology’s significance: “Coriolis flowmeters remain fundamental to flow measurement markets. Manufacturers consistently invest in research and development across multiple dimensions. Improvements span accuracy, materials, size ranges, and application-specific designs. These meters now handle critical hydrogen and renewable natural gas measurements alongside traditional CNG and LNG applications. We anticipate Coriolis technology will lead measurement requirements throughout the energy transition, maintaining its upward trajectory through continuous innovation.”

Application Scenario: Real-World Implementation

Consider a chemical processing facility facing measurement challenges with corrosive fluids. By implementing titanium-constructed Coriolis meters, the plant achieves accurate flow measurement despite aggressive chemicals. The meters’ diagnostic capabilities predict maintenance needs before failures occur, preventing unplanned downtime. In LNG transfer operations, large-diameter Coriolis meters provide custody transfer accuracy while withstanding demanding process conditions. The technology’s minimal maintenance requirements prove particularly valuable for remote installations where service personnel availability remains limited.

Market Trend Analysis

The flow measurement industry increasingly prioritizes accuracy and reliability across expanding applications. Coriolis technology’s adaptability to both large-scale energy transfer and precision laboratory applications demonstrates its versatility. As industries transition toward renewable energy sources, Coriolis meters evolve to meet new measurement challenges. The technology’s proven performance in traditional oil and gas applications provides a solid foundation for expansion into hydrogen and renewable natural gas markets. This adaptability ensures continued market relevance amid changing energy landscapes.

About Flow Research

Flow Research stands as the premier independent market research firm specializing in flowmeter and instrumentation markets worldwide. Established in 1998 and headquartered in Wakefield, Massachusetts, the company maintains exclusive focus on flow measurement technologies. Their comprehensive market studies incorporate extensive interviews with suppliers, distributors, and end-users. The organization maintains particular expertise in energy sector applications, including oil and gas production measurement and renewable energy technologies.

Frequently Asked Questions

What factors contribute to Coriolis flowmeters’ market dominance?

Superior accuracy, minimal maintenance requirements, and continuous technological innovation maintain Coriolis flowmeters’ market position. Their versatility across industries and applications further strengthens their competitive advantage.

How do straight tube designs improve upon previous models?

Straight tube configurations eliminate clogging issues common in bent tube designs while reducing installation space requirements. This advancement expands suitable applications to include fluids with suspended solids.

What makes Coriolis meters suitable for custody transfer applications?

Their high accuracy certification (APA-11 for natural gas) and reliability make them ideal for fiscal measurement where measurement precision directly impacts financial transactions.

How do newer materials enhance Coriolis meter performance?

Advanced materials like titanium and super duplex stainless steel improve corrosion resistance, extend service life, and enable measurement of more aggressive process fluids.

What industries benefit most from Coriolis flowmeter technology?

Oil and gas, chemical processing, pharmaceuticals, and food production industries derive significant value from Coriolis meters’ accuracy, reliability, and minimal maintenance requirements.

LEAVE A COMMENT