Cryogenic Nitrogen Flow Measurement Solutions

Accurate Cryogenic Nitrogen Measurement Using Coriolis Mass Flow Technology

The Critical Need for Precision in Nitrogen Applications

Nitrogen serves as a fundamental industrial gas across multiple sectors including electronics manufacturing, food preservation, and medical research. This versatile substance exists in gaseous, liquid, and solid states depending on temperature and pressure conditions. The extreme density variations and phase changes present significant measurement challenges, particularly with cryogenic liquid nitrogen at -196°C.

Limitations of Traditional Flow Measurement Methods

Conventional flow meters encounter substantial difficulties in cryogenic environments. Turbine, vortex, and orifice plate meters depend on moving components and stable fluid properties. These devices frequently fail when confronted with nitrogen’s dramatic density fluctuations and phase transitions. Their volumetric measurement approach proves inadequate when dealing with substances whose volume changes significantly with temperature variations.

Nitrogen’s Physical Properties and Measurement Implications

Nitrogen undergoes remarkable transformations under different thermal and pressure conditions. At standard atmospheric pressure, it boils at -195.8°C. Even minor environmental changes can trigger rapid vaporization, creating problematic gas-liquid mixtures. The density disparity between gaseous and liquid states exceeds 700 times, rendering volume-based measurements highly unreliable.

| State | Typical Conditions | Density (kg/m3) | Characteristics |

| Gas | 25°C, 1 atm | ≈1.17 | Low density, compressible |

| Liquid | -196°C, 1 atm | ≈808 | High density, cryogenic |

| Supercritical Fluid | >126.2 K, >3.39 MPa | ∼100-500 | Hybrid gas-liquid traits |

Cryogenic Measurement Obstacles

Three primary challenges complicate cryogenic nitrogen measurement:

Phase Transition Instability

Minor pressure or temperature fluctuations cause immediate flashing, creating two-phase flow conditions that disrupt volumetric measurement accuracy.

Material Compatibility Issues

Extreme cold causes metal contraction and frost formation, potentially damaging equipment and interrupting signal transmission.

Density Variability

Nitrogen’s physical properties change dramatically with temperature shifts, necessitating measurement methods independent of density considerations.

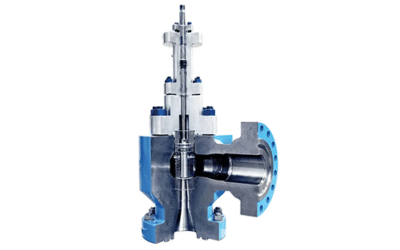

Coriolis Technology Advantages for Cryogenic Service

Coriolis mass flow meters provide optimal solutions for these challenges through several key features:

Cryogenic Material Construction

Manufacturers use 316L stainless steel or specialized alloys like Hastelloy that maintain structural integrity and performance at temperatures down to -200°C.

Phase Change Immunity

The Coriolis effect measures mass directly, ensuring accuracy regardless of whether nitrogen exists as liquid, gas, or in mixed-phase states.

Maintenance-Free Operation

With no moving parts subject to freezing or wear, these meters deliver long-term reliability in demanding cryogenic applications.

Integrated Temperature Monitoring

Built-in temperature measurement capabilities allow continuous monitoring of process conditions without additional instrumentation.

Exceptional Measurement Precision

Typical accuracy within ±0.2% of reading ensures reliable custody transfer and process control for critical applications.

Technical Specifications and Implementation Considerations

Coriolis meters for cryogenic service typically feature:

Temperature Range

Operational capability from -200°C to elevated temperatures

Measurement Accuracy

±0.1% to ±0.5% of reading depending on specific model and application

Material Options

316L stainless steel standard, with cryogenic alloys available for specialized requirements

Communication Protocols

4-20 mA, pulse outputs, RS485, HART, and PROFIBUS DP interfaces

Size Availability

DN4 (1/8 inch) to DN200 (8 inch) pipeline diameters

Practical Implementation Guidance

Successful Coriolis meter installation requires careful planning. Ensure proper thermal isolation to prevent ice formation and maintain signal integrity. Verify material compatibility with specific nitrogen purity requirements. Consider installation orientation and support requirements to minimize stress on flow tubes. Implement comprehensive commissioning procedures including zero verification at operating temperature.

Industry Applications and Future Trends

Coriolis technology has become the standard for nitrogen measurement in LNG facilities, semiconductor manufacturing, pharmaceutical production, and research laboratories. The technology’s reliability and accuracy support critical processes including cryogenic storage, inert gas blanketing, and precision cooling applications. Ongoing developments focus on enhanced diagnostics, reduced pressure drop, and expanded temperature ranges for emerging cryogenic applications.

Frequently Asked Questions

Why do traditional flow meters fail with cryogenic nitrogen?

Conventional meters rely on stable fluid properties and moving parts that malfunction under extreme cold and phase change conditions.

How does the Coriolis principle ensure measurement accuracy?

The technology measures mass directly rather than volume, making it immune to density changes and phase transitions.

What materials work best for cryogenic flow measurement?

316L stainless steel and specialized alloys like Hastelloy maintain performance at extremely low temperatures.

Can Coriolis meters handle two-phase flow conditions?

Yes, they maintain accuracy even when nitrogen exists as a mixture of liquid and gas phases.

What maintenance do Coriolis meters require in cryogenic service?

Their lack of moving parts and robust construction typically requires minimal maintenance beyond periodic verification.

LEAVE A COMMENT