Danfoss Expands Chinese Green Tech Manufacturing

Danfoss Strengthens Global Presence with New Chinese Manufacturing Campus

Strategic Expansion in Green Technology

Danish engineering leader Danfoss has launched its largest worldwide production facility in Haiyan, China. The new 126,000 square meter complex significantly expands the company’s regional manufacturing capacity. This development aligns with China’s increasing focus on sustainable industrial solutions and environmental responsibility.

Comprehensive Manufacturing Capabilities

The enhanced Haiyan campus now integrates production across all three Danfoss business divisions. Moreover, it features two specialized Application Development Centers serving Power Solutions and Climate Solutions segments. These facilities maintain identical quality standards to Danfoss operations in Europe and North America.

Leadership Perspectives on Market Commitment

Kim Fausing, Danfoss President and CEO, emphasized China’s crucial role in global strategy during the opening ceremony. “We maintain strong confidence in the Chinese market,” Fausing stated. “This investment supports our LEAP 2030 strategic framework while contributing to China’s low-carbon transition through advanced innovation.”

International Collaboration for Sustainable Development

Anders Siegumfeldt, Deputy Head of Mission at Denmark’s Beijing Embassy, highlighted the project’s diplomatic significance. “Danfoss’s expansion reflects our nations’ shared environmental ambitions,” he noted. The ambassador presented a commemorative plate celebrating 75 years of Danish-Chinese relations.

Local Economic Impact and Partnership

Arthur Xu, President of Danfoss China, acknowledged the company’s three-decade presence in China. “Our Haiyan operation has become a vital global innovation center,” Xu commented. “Local government support has been instrumental to our success and regional economic development.”

Sustainable Operations and Energy Management

The new campus implements Danfoss’s three-phase decarbonization strategy: Reduce, Reuse, and Re-source. Furthermore, a 20-year green power agreement with CGN New Energy ensures complete renewable electricity coverage for all Haiyan facilities.

Industrial Automation Applications

Danfoss technologies enable significant energy efficiency improvements across multiple sectors. For instance, their variable frequency drives can reduce motor energy consumption by up to 40% in industrial applications. Similarly, advanced heat exchangers optimize thermal management in building climate systems.

Expert Commentary: Industry Trends

The industrial automation sector increasingly prioritizes energy-efficient solutions. Danfoss’s expansion demonstrates how established manufacturers are adapting to global sustainability demands. Companies integrating green technologies into core operations will likely maintain competitive advantages as environmental regulations tighten worldwide.

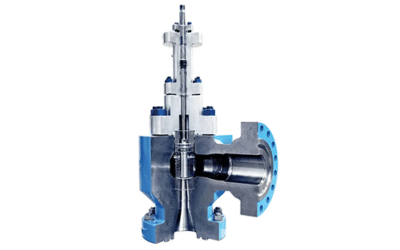

Implementation Scenario: Manufacturing Plant Retrofit

A typical Chinese automotive components manufacturer recently implemented Danfoss hydraulic solutions and PLC-controlled compressors. Consequently, the facility achieved 25% energy reduction while maintaining production output. The return on investment was realized within 18 months through lower operational costs.

Frequently Asked Questions

What makes China strategically important for industrial automation companies?

China represents both a major manufacturing hub and the world’s largest market for green technologies. The country’s dual focus on industrial modernization and environmental targets creates significant opportunities for automation providers.

How do variable frequency drives contribute to energy efficiency?

These devices precisely control motor speed to match actual load requirements. Therefore, they eliminate energy waste associated with conventional fixed-speed operations, typically reducing electricity consumption by 20-50%.

What is the significance of Application Development Centers?

These facilities enable customized solution development for specific regional requirements. Local technical support accelerates implementation while ensuring optimal performance in unique operating conditions.

How does Danfoss’s decarbonization approach benefit industrial customers?

The Reduce-Reuse-Re-source methodology provides a practical framework for sustainability improvements. Companies can implement proven technologies incrementally, managing costs while achieving meaningful environmental targets.

What role does industrial automation play in sustainable manufacturing?

Advanced control systems optimize resource utilization across production processes. Energy management, predictive maintenance, and precision operations collectively reduce environmental impact while improving profitability.

LEAVE A COMMENT