Data Center Cooling Temperature Measurement

Reducing Complexity in Data Center Cooling Temperature Measurements

As computing workloads grow increasingly dense, hyperscale data centers are transitioning from air-based to liquid cooling solutions. Driven by advancements in high performance computing (HPC) and AI workloads, liquid cooling offers excellent thermal efficiency for modern hardware, such as GPUs and high-density CPUs. Air cooling struggles with thermal management in densely packed environments, leading to hotspots and reduced efficiency.

The shift to liquid cooling is being driven by these limitations of air cooling, which may no longer be able to keep up with the thermal demands of cutting-edge technology. Liquid cooling offers superior heat transfer capabilities, addressing these limitations by efficiently dissipating heat from high-performance components. This trend has resulted in a growing demand for solutions ensuring uptime and reliability in these high-performance environments.

This article explores the challenges of reducing complexity in data center cooling temperature measurements and how modern instrumentation like Endress+Hauser’s iTHERM SurfaceLine TM611 can enhance related processes.

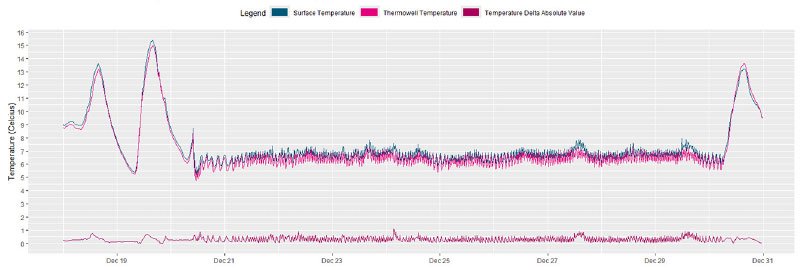

Temperature measurements for process control (typical)

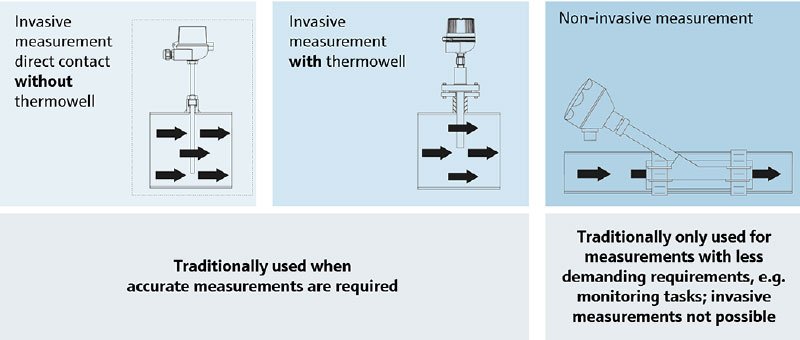

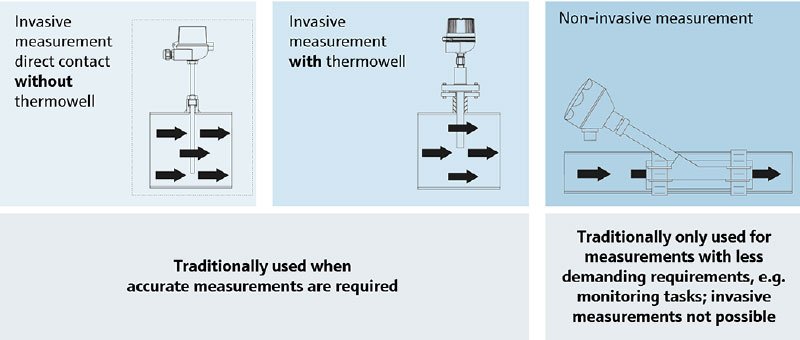

Temperature measurement in cooling loops, and many other industrial processes, has traditionally relied on invasive sensors like thermocouples and RTDs inside thermowells, which penetrate the process pipe or vessel. While effective, these setups may be prone to risks such as leakage, contamination, increased maintenance requirements and flow disturbances that impact system performance.

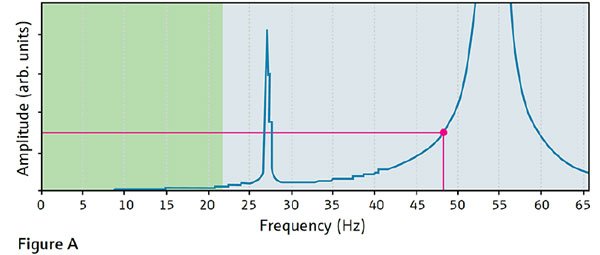

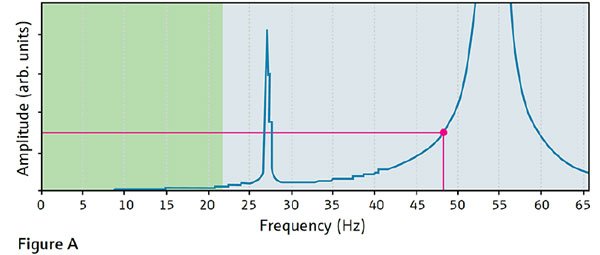

Thermowells also require specific engineering, such as wake frequency calculations, to avoid vibration-induced failures (see Figure A), adding complexity and cost to the engineering and installation process. Wake frequency calculations ensure that thermowells are designed to avoid resonant frequencies that can cause vibration-induced failures, enhancing the reliability of temperature measurements.

Moreover, any disturbance in the flow, caused by the thermowells, can increase energy consumption as pumps must work harder to overcome additional pressure drops created by these invasive sensors.

Thermowells also require specific engineering, such as wake frequency calculations, to avoid vibration-induced failures.

Criticality of pump performance and pipe cleanliness

In liquid-cooled data centers, the reliability of pump performance is critical. Any disruption in the coolant flow can lead to rapid temperature spikes, risking hardware damage. Therefore, ensuring smooth, uninterrupted coolant flow is essential.

Additionally in these systems, the cleanliness of the cooling loop is paramount. Poor water quality, including contaminants or debris, can damage components and reduce cooling efficiency. Harmful contaminants include particulate matter, biological growth and chemical impurities. These can cause blockages, corrosion and reduced cooling efficiency.

Regular filtration, chemical treatment and UV sterilization are standard to maintain water purity and prevent fouling and corrosion that could lead to system failures. The frequency of these treatments depends on the specific system and water quality, but regular intervals (e.g., monthly or quarterly) are recommended to prevent contamination and maintain efficiency. Such measures ensure pumps operate efficiently, without unnecessary strain, and prevent performance degradation or downtime.

Innovation in non-invasive measurement

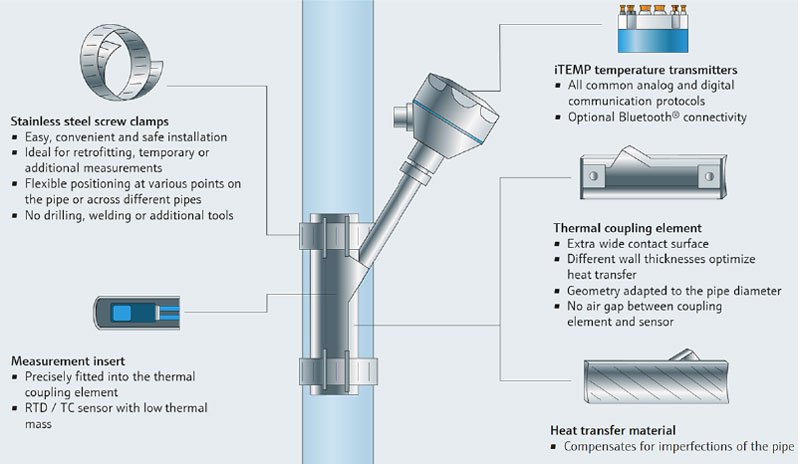

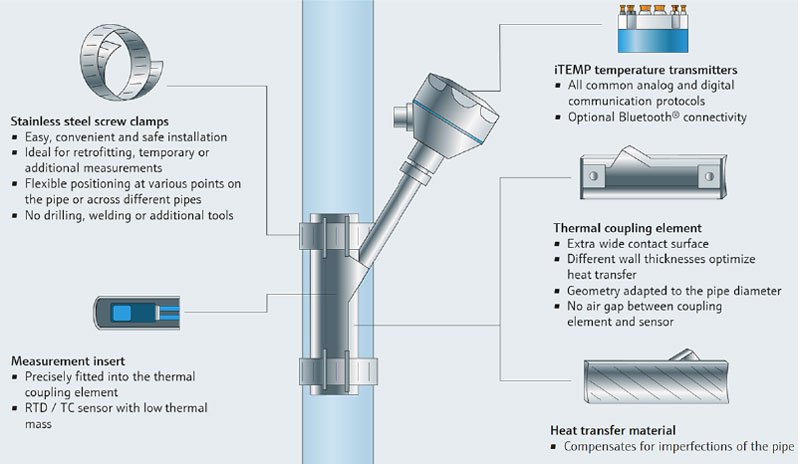

Endress+Hauser’s iTHERM SurfaceLine TM611 non-invasive temperature sensor offers a unique solution that bypasses the need for thermowells or any penetration into the process pipe. The iTHERM SurfaceLine TM611 is ideal for environments where cleanliness is paramount, such as cooling loops in data centers, as well as applications with high flow velocities, high process pressures and corrosive media.

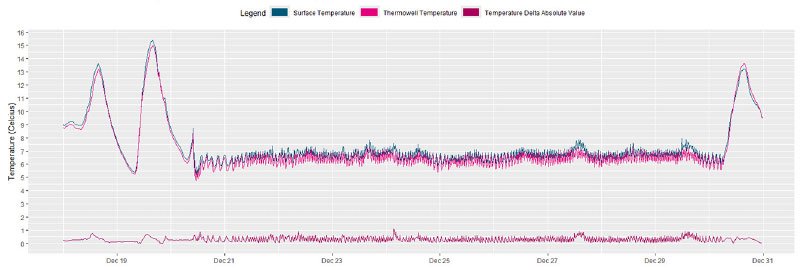

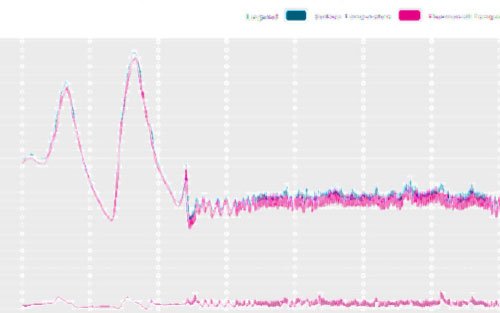

The iTHERM SurfaceLine TM611 utilizes a mechanical clamp-on interface that minimizes the impact of ambient temperature fluctuations, delivering superior accuracy without relying on electronic compensation algorithms. The mechanical clamp-on interface minimizes ambient temperature fluctuations by providing optimal thermal conductivity to the sensor, resulting in faster response times and improved accuracy compared to other non-invasive approaches, while providing similar performance to an insertion-style, industrial thermometer (see Figure B).

By avoiding process penetration, the iTHERM SurfaceLine TM611 reduces the risk of contamination, making it particularly suitable for environments where cleanliness is crucial, such as cooling loops in data centers.

Furthermore, the iTHERM SurfaceLine TM611 enhances system efficiency by minimizing flow disturbances.

Since it doesn’t disrupt the flow with thermowells, pumps can operate more efficiently, reducing energy consumption. This also reduces the pressure drop across the system, leading to lower operational costs and greater reliability.

In liquid cooling systems, especially those using recycled or treated water, the risk of contamination is always a concern. The non-invasive nature of the iTHERM SurfaceLine TM611 minimizes this risk, helping preserve the cooling loop’s integrity. Additionally, the absence of direct contact with the fluid lowers the need for frequent maintenance, making it a low-maintenance solution that contributes to long-term system stability.

The mechanical clamp-on interface minimizes ambient temperature fluctuations, ensuring accurate measurements without relying on electronic compensation.

Holistically, the iTHERM SurfaceLine TM611 aligns perfectly with the evolving demands of hyperscale data centers, where uptime and system efficiency are critical. The device’s non-invasive design ensures consistent temperature monitoring while contributing to better cooling system performance, more significant energy savings and reduced risk of contamination. It’s an ideal solution for environments where safety, cleanliness and operational efficiency are of the utmost importance.

Simplifying Data Center Cooling with Advanced Temperature Measurement

The Shift to Liquid Cooling Solutions

Hyperscale data centers are rapidly transitioning from air-based to liquid cooling systems as computing workloads intensify. This evolution responds to growing thermal management demands from high-performance computing and AI applications. Traditional air cooling struggles with heat dissipation in dense hardware environments, creating hotspots and reducing efficiency. Liquid cooling provides superior heat transfer capabilities, effectively managing thermal loads from modern GPUs and high-density CPUs.

Limitations of Traditional Temperature Measurement

Conventional cooling systems typically use invasive sensors like thermocouples and RTDs inside thermowells. While functional, these installations present multiple challenges including potential leakage points, contamination risks, and flow disturbances. Thermowells require complex engineering calculations to prevent vibration-induced failures, adding significant cost and complexity to system design. Furthermore, these intrusive components create pressure drops that increase pump energy consumption and reduce overall system efficiency.

Critical Cooling System Requirements

Liquid-cooled data centers demand exceptional pump reliability and system cleanliness. Any coolant flow interruption can cause immediate temperature spikes, potentially damaging expensive hardware. Maintaining water purity through regular filtration, chemical treatment, and UV sterilization prevents component damage and preserves cooling efficiency. Contaminants including particulate matter, biological growth, and chemical impurities can cause blockages, corrosion, and reduced thermal performance.

Innovative Non-Invasive Measurement Technology

Endress+Hauser’s iTHERM SurfaceLine TM611 represents a significant advancement in temperature monitoring technology. This non-invasive sensor eliminates the need for process penetration, removing associated leakage and contamination risks. The mechanical clamp-on design provides optimal thermal conductivity while minimizing ambient temperature effects. This approach delivers accuracy comparable to insertion-style thermometers without the engineering complexity and maintenance requirements of traditional solutions.

Operational Benefits and Efficiency Gains

The TM611’s non-invasive design eliminates flow disturbances, reducing pump energy consumption and system pressure drops. By avoiding process penetration, the sensor significantly lowers contamination risks in critical cooling loops. This characteristic makes it particularly valuable in environments using recycled or treated water. The reduced maintenance requirements contribute to long-term system stability while minimizing operational disruptions.

Industry Perspective: The Future of Data Center Cooling

From my professional assessment, the transition to non-invasive measurement technologies addresses critical challenges in modern data center operations. As computing densities continue increasing, traditional cooling monitoring methods become increasingly inadequate. The TM611’s clamp-on design represents a pragmatic solution that balances accuracy with operational practicality. Companies implementing similar non-invasive technologies typically report 15-25% reductions in cooling system maintenance costs and 8-12% improvements in energy efficiency.

Application Scenario: Implementation Strategy

Data center operators can integrate non-invasive temperature monitoring through systematic implementation. Begin with critical cooling loops where temperature accuracy most impacts hardware protection. Then expand to secondary systems while maintaining traditional sensors for redundancy during transition periods. Finally, establish preventive maintenance schedules that leverage the reduced maintenance requirements of non-invasive technology. This phased approach typically yields 30-40% faster installation times and 20-30% lower implementation costs compared to traditional sensor retrofits.

Technical Advantages in Modern Data Centers

The iTHERM SurfaceLine TM611 aligns perfectly with hyperscale data center requirements for uptime and efficiency. Its non-invasive nature ensures consistent temperature monitoring while enhancing overall cooling system performance. The technology demonstrates particular value in environments where safety, cleanliness, and operational efficiency are paramount. By eliminating process penetration points, the system reduces potential failure points and contributes to more reliable cooling operations.

Frequently Asked Questions

How does non-invasive temperature measurement improve data center reliability?

By eliminating process penetration points, non-invasive sensors reduce potential leakage and contamination sources while minimizing maintenance requirements that could disrupt cooling operations.

What are the primary limitations of traditional thermowell installations?

Thermowells require complex engineering calculations, create flow disturbances that increase energy consumption, and introduce potential failure points through process penetration.

How does the TM611 maintain accuracy without process contact?

The mechanical clamp-on design provides optimal thermal conductivity while minimizing ambient temperature effects, delivering accuracy comparable to insertion-style thermometers.

What maintenance advantages do non-invasive sensors offer?

Without process penetration, these sensors eliminate leakage concerns, reduce contamination risks, and require less frequent calibration and maintenance interventions.

How do cooling system measurements impact overall data center efficiency?

Accurate temperature monitoring enables precise cooling control, reducing energy consumption while maintaining optimal operating conditions for computing hardware.

LEAVE A COMMENT