Digital Twin Testbeds Expand

Digital Twin Consortium Expands Innovation with Eight New Testbeds

The Consortium’s testbed program now includes 16 collaborative projects advancing digital twin technology across multiple industries.

Major Expansion of Digital Twin Testing Program

The Digital Twin Consortium (DTC) has significantly expanded its testing capabilities. The organization added eight new testbeds to its development program. This brings the total number of active testbeds to sixteen. Members now enjoy unprecedented access to early-stage development resources. They can model, simulate, and optimize digital twin solutions effectively.

Leadership Emphasizes Global Collaboration

“We’re excited to announce these innovative digital twin testbeds,” said Dan Isaacs, DTC’s GM and CTO. “We’re seeing strong worldwide member interest in our collaborative program. Members already utilize this program to develop AI-powered intelligent digital twins. They’re also advancing generative AI digital twin technologies. These efforts drive tomorrow’s digital transformation.”

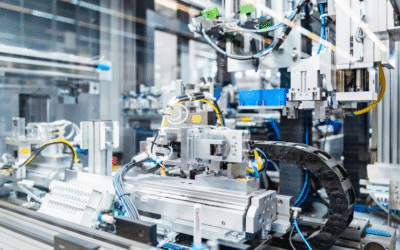

TWINSENSE: AI-Powered Virtual Sensing

This testbed demonstrates real-time virtual measurement capabilities. It addresses challenging measurement scenarios across industrial assets. The technology monitors inaccessible or costly variables through digital twins. It also calibrates AI novelty detection using transfer learning. This approach combines virtual and real-world data effectively. The system enables proactive maintenance strategies. It improves maintenance accuracy by an impressive 40%. Lead Developer: Aingura IIoT

FAB: Mobile Manufacturing for Disaster Response

The Factory-in-a-Box testbed represents innovative crisis response technology. It’s a mobile, modular digital twin-enabled manufacturing unit. These units produce critical energy components in disaster zones. They reduce transport costs and logistics burdens significantly. The system minimizes essential infrastructure downtime. It enables localized, resilient production with minimal setup requirements. Remote coordination occurs through digital twin interfaces. Lead Developers: DRG Solutions and Oak Ridge High School

SAFESME: Rapid Equipment Commissioning

This testbed focuses on small to medium enterprise manufacturing equipment. It validates digital twin-driven commissioning for injection molding and packaging machines. The system enables cost-effective digital transformation for SMEs. It achieves rapid automated onboarding in under five minutes per asset. Setup time and operator effort reduce dramatically. The solution maintains high model alignment and API performance. Importantly, it requires no expensive PLC upgrades. Lead Developer: HS Soft

Q-Smart: Quantum-Secure Smart Homes

Q-Smart validates a cognitive, secure, self-learning home system. It uses decentralized open-source components as its foundation. The system creates personal cognitive hubs through wireless mesh networks. Dynamic live 3D models (digital twins) provide comprehensive monitoring. Multi-agent AI frameworks and XR interfaces enable sophisticated control. The technology emphasizes edge-native processing for data privacy. It incorporates quantum-safe protocols for future-proof security. Energy consumption reduces by up to 25%. Lead Developer: WINNIO

TRANSFORM: Dynamic Geospatial Representation

TRANSFORM systematically converts static 2D data into dynamic 4D representations. It creates real-time updated geospatial models using digital twins. The testbed integrates wireless mesh networks and sensor systems. Self-learning AI frameworks monitor and predict environmental conditions. XR interfaces enable seamless human-system interactions. Applications include smart city infrastructure and emergency services. Lead Developer: EDX Technologies

Healthcare and Education Innovations

Three testbeds address critical social infrastructure challenges. The AEGIS testbed improves student outcomes through multi-agent systems. ENGAGE identifies and supports at-risk students using comprehensive digital twins. SYNTHEKID transforms healthcare delivery for chronic kidney disease patients. This privacy-preserving system enables scenario planning without compromising confidentiality.

Technical Framework and Membership Benefits

The Digital Twin Testbed Program implements DTC’s Composability Framework. This includes the Business Maturity Model and Platform Stack Architecture. The Capabilities Periodic Table provides additional structural guidance. A capabilities-focused maturity assessment evaluates advanced technologies. These include Generative AI and multi-agent systems.

Author’s Insight: The Industrial Impact

This expansion represents more than additional testbeds—it signals digital twins’ maturation from concept to practical implementation. The SAFESME testbed particularly interests industrial automation professionals. Enabling digital twin commissioning in under five minutes without PLC upgrades addresses a major adoption barrier for small manufacturers. For control systems engineers, the TWINSENSE virtual sensing capabilities could revolutionize how we monitor inaccessible process variables. These testbeds demonstrate that digital twin technology is moving beyond large enterprises to become accessible across the manufacturing spectrum.

Application Scenario: Predictive Maintenance Implementation

Challenge: A manufacturing plant needs to monitor bearing wear in inaccessible conveyor systems, facing unexpected downtime and high maintenance costs.

Solution: Implementation of TWINSENSE virtual sensing technology through digital twins.

Outcome: The plant achieves 40% improvement in maintenance accuracy, reduces unplanned downtime by 60%, and extends equipment life through proactive bearing replacement.

About Digital Twin Consortium

The Digital Twin Consortium serves as the authority in digital twin technology. It brings together industry, government, and academic stakeholders. The organization drives consistency in vocabulary, architecture, and security. It advances digital twin interoperability across multiple industries. These range from aerospace to natural resources.

Frequently Asked Questions (FAQs)

What is the Digital Twin Consortium’s Testbed Program?

The program provides members with collaborative environments to develop, test, and validate digital twin technologies across various applications and industries.

How many testbeds does the DTC now operate?

With the addition of eight new testbeds, the Consortium now operates sixteen active testbeds in its development program.

Which testbed focuses on manufacturing equipment commissioning?

The SAFESME testbed specifically addresses rapid digital twin commissioning for SME manufacturing equipment, achieving setup in under five minutes.

What industrial benefits does the TWINSENSE testbed provide?

TWINSENSE enables virtual sensing of inaccessible variables and improves maintenance accuracy by 40% through AI-powered proactive maintenance.

How does the FAB testbed support disaster response?

The Factory-in-a-Box testbed provides mobile, digital twin-enabled manufacturing units that produce critical components directly in disaster-affected areas.

LEAVE A COMMENT