Equipment Strategy: Replace, Repair or Retrain

Making Strategic Equipment Decisions: When to Replace, Repair or Retrain

The Manufacturing Crossroads

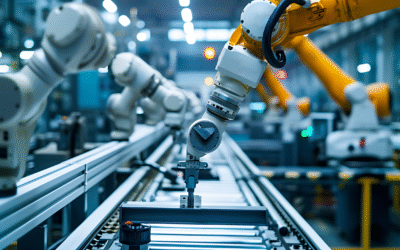

Every manufacturing operation eventually faces critical equipment decisions. Aging machinery, evolving technology, and changing workforce capabilities create complex choices. Manufacturers must determine whether to continue maintaining existing equipment, invest in new technology, or enhance operator skills through targeted training programs.

Step 1: Comprehensive Equipment and Skills Assessment

Begin by evaluating both machinery performance and operator capabilities. Analyze repair frequency, production demands, and maintenance costs compared to new equipment investment. Consider whether older machines still meet quality standards and integrate effectively with newer equipment. Simultaneously, assess whether operators have the skills to maximize existing equipment potential or require updated training.

Step 2: Cost-Benefit Analysis: Repair vs. Replacement

Calculate total cost of ownership for existing equipment versus new acquisitions. Consider that only 15% of a machine’s lifetime cost comes from the initial purchase, while 85% accumulates through operational expenses. Evaluate whether repeated repairs justify continued investment or if replacement provides better long-term value through improved reliability and performance.

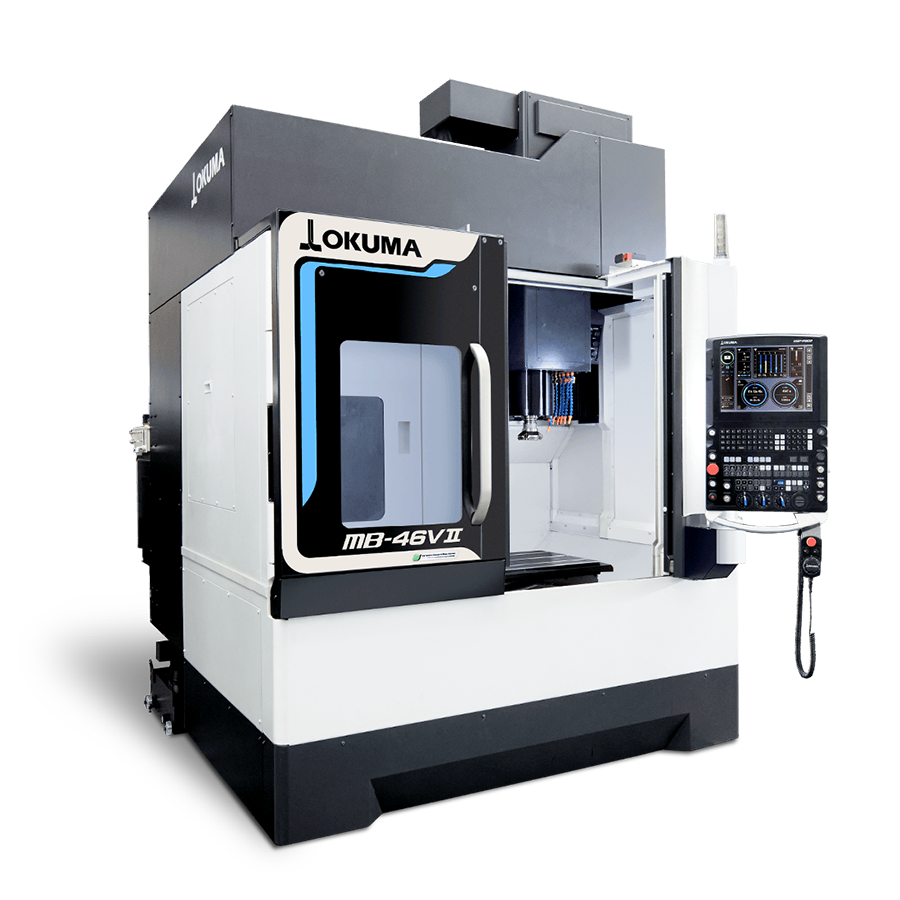

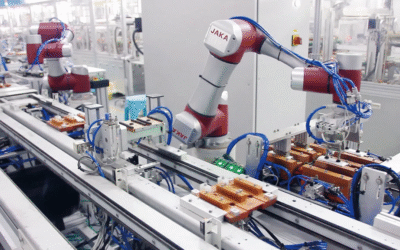

Step 3: Advantages of Modern Equipment Technology

New machinery offers significant technological advancements unavailable in older models. Modern CNC controls provide enhanced processing power, energy efficiency, and security features. These systems enable automation integration and expanded manufacturing capabilities while building customer confidence through reliable, precision manufacturing.

Step 4: Realizing New Equipment Benefits

Modern equipment reduces scrap rates, minimizes rework, and improves production scheduling reliability. New machines with advanced controls allow operators to run multiple programs simultaneously while maintaining precision. These improvements directly impact profitability through reduced material waste and increased operational efficiency.

Strategic Implementation Considerations

Equipment decisions should align with overall business strategy and financial capabilities. Various financing options exist for businesses preferring to avoid large capital expenditures. Additionally, many manufacturers implement phased replacement strategies, prioritizing critical equipment while maintaining operational continuity.

Industry Expert Perspective

Manufacturing efficiency specialists emphasize that equipment decisions require balancing multiple factors. “The most successful manufacturers conduct regular technology assessments,” notes industrial automation consultant Sarah Mitchell. “They recognize that both equipment capabilities and operator skills must evolve together to maintain competitiveness.”

Implementation Scenario: Machine Shop Modernization

A precision machining company faced increasing scrap rates and maintenance costs on aging CNC equipment. After comprehensive analysis, they implemented a phased replacement strategy combined with operator training. This approach reduced scrap by 42% and increased overall equipment effectiveness by 28% within one year.

Frequently Asked Questions

What are the key indicators that equipment needs replacement?

Frequent breakdowns, declining precision, high maintenance costs, and inability to meet current production demands signal replacement consideration.

How should manufacturers calculate total equipment ownership costs?

Include purchase price, installation, maintenance, energy consumption, tooling, and operational labor costs over the equipment’s expected lifespan.

What training benefits can offset equipment replacement?

Enhanced operator skills can improve existing equipment utilization by 15-25%, potentially delaying capital investment through optimized performance.

How does modern equipment impact manufacturing sustainability?

New machinery typically offers 20-40% better energy efficiency and reduces material waste through improved precision and control systems.

What financing options exist for equipment modernization?

Manufacturers can explore equipment leasing, financing programs, phased replacement strategies, and government incentives for technology upgrades

LEAVE A COMMENT