Festo Automation for Semiconductor Production

Festo Demonstrates Integrated Automation for Semiconductor Wafer Production

Streamlined Semiconductor Manufacturing

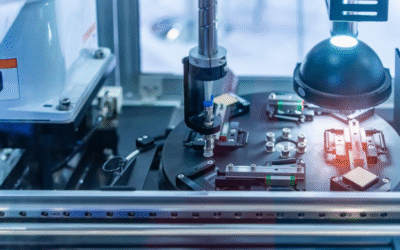

Festo showcases interconnected automation solutions for semiconductor production. The demonstration focuses on critical wafer handling and processing stages. This integrated approach addresses key challenges in semiconductor manufacturing.

Advanced Wafer Handling Technology

The system features an innovative central hub with inverted gantry technology. This solution provides a cost-effective alternative to traditional SCARA robots. The gantry efficiently transfers wafers from FOUP carriers to processing stations.

Integrated Alignment Innovation

Festo’s unique end effector combines gripping and alignment functions. This compact device achieves sub-micron positioning accuracy. Consequently, it reduces system complexity while improving process reliability.

Precision Coating Applications

Module 1 demonstrates wet chemical processing capabilities. Festo Mass Flow Controllers ensure contaminant-free environments. The coating station utilizes electric linear axes for precise chemical application.

Vacuum Processing Expertise

Module 2 showcases vacuum environment handling for processes like dry etching. The system manages smooth transitions into vacuum chambers. Pneumatic micro-positioning systems provide micrometer-level accuracy.

Industry-Specific Solutions

Festo addresses critical semiconductor manufacturing requirements. Their portfolio includes cleanroom-compatible components and nitrogen purge systems. Additionally, they offer digitalization tools and AI-driven maintenance solutions.

Technical Advantages

The integrated system delivers multiple benefits for semiconductor manufacturers:

- Reduced equipment complexity through function integration

- Enhanced positioning accuracy with sub-micron capabilities

- Improved process reliability through controlled environments

- Cost optimization using alternative automation technologies

Industry Perspective

Semiconductor manufacturing demands unprecedented precision and reliability. Festo’s integrated approach demonstrates how component-level innovations can transform entire production workflows. The combination of pneumatic and electrical technologies provides optimal solutions for different process requirements.

Application Scenario

A typical semiconductor fab implementing this technology could achieve significant improvements. Wafer handling time might reduce by 25% while alignment accuracy improves substantially. The integrated approach also minimizes maintenance requirements and system footprint.

Future Development Trends

Semiconductor automation continues evolving toward higher integration levels. Future systems will likely incorporate more AI-driven optimization and predictive maintenance capabilities. Festo’s demonstration provides a glimpse into next-generation semiconductor manufacturing platforms.

About Festo U.S.

Festo stands as a leading automation technology provider for industrial and process applications. The company brings a century of innovation experience, including five decades in the U.S. market. Festo’s comprehensive approach includes both automation solutions and workforce development programs.

Frequently Asked Questions

How does Festo’s gantry compare to SCARA robots?

The inverted gantry offers cost-effective wafer handling with comparable precision. It provides reliable performance for standard semiconductor applications.

What accuracy levels can the wafer aligner achieve?

The integrated aligner delivers sub-micron positioning accuracy. This meets stringent requirements for advanced semiconductor processes.

Does Festo provide cleanroom-compatible components?

Yes, Festo offers comprehensive cleanroom-certified automation components. These meet semiconductor industry contamination control standards.

How does the system handle vacuum environment transitions?

Specialized valves manage smooth chamber transitions. Pneumatic systems ensure gentle handling throughout vacuum processes.

What support does Festo offer for semiconductor manufacturers?

Festo provides complete solutions including components, digital tools, and technical training. Their expertise spans both front-end and back-end processes.

LEAVE A COMMENT