Flexxbotics Robotics Technology Award Finalist

Flexxbotics Gains Industry Recognition for Revolutionary Robotics Technology

Groundbreaking Technology Achievement

Flexxbotics has earned finalist status in the Humanoid Robotics Industry Awards 2025. The company’s FlexxCORE technology competes in the Groundbreaking Technology category. This recognition highlights significant advancements in robot-driven manufacturing solutions.

Voting Opportunity for Industry Professionals

The awards program currently accepts public voting through the official platform. Industry participants can support their preferred technologies until the November deadline. Therefore, this process ensures community involvement in determining the winners.

Core Technology Capabilities

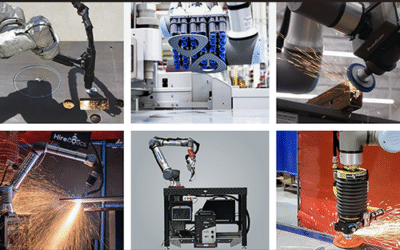

FlexxCORE represents the fundamental innovation within the Flexxbotics ecosystem. This technology enables seamless communication between robotic systems and manufacturing equipment. Moreover, it coordinates interactions between humanoid robots, factory systems, and human operators.

Transforming Manufacturing Environments

The technology allows robots to interpret machine operations and processing routines. It facilitates understanding of job status and operational parameters. Consequently, this capability supports more sophisticated production scenarios and workflow management.

Advancing Smart Manufacturing Vision

This nomination demonstrates Flexxbotics’ commitment to redefining industrial automation. The company bridges critical gaps between automation systems and operational adaptability. As a result, manufacturers can implement more digitalized and collaborative factory environments.

Industry Leadership Perspective

“We appreciate this recognition of our manufacturing technology,” stated Tyler Bouchard, Flexxbotics CEO. “Our solution enables humanoid robots to integrate seamlessly with existing factory infrastructure. We believe this technology forms the foundation for future smart factories.”

Awards Program Significance

The Humanoid Robotics Industry Awards, collaborating with Novanta, honor exceptional contributions to robotics development. The program acknowledges technologies and organizations shaping humanoid robotics evolution. Winners will be announced following the public voting process.

Technical Analysis: Robotics Integration Challenge

From a technical standpoint, FlexxCORE addresses one of manufacturing’s persistent challenges: system interoperability. Traditional factories often struggle with equipment communication barriers. This technology potentially creates unified manufacturing ecosystems where robots and machines share operational data.

Application Scenario: Human-Robot Collaboration

Imagine automotive assembly lines where humanoid robots work alongside traditional automation and human technicians. FlexxCORE would enable these diverse systems to coordinate complex tasks seamlessly. Such environments could dynamically adjust workflows based on real-time production demands.

Frequently Asked Questions

What specific problem does FlexxCORE technology solve?

FlexxCORE enables communication between different manufacturing systems that typically operate independently. It creates interoperability between robots, machines, and control systems.

How does this technology benefit existing manufacturing facilities?

It allows manufacturers to integrate advanced robotics without replacing current equipment. This approach protects existing investments while enabling technological advancement.

What distinguishes FlexxCORE from other robotics solutions?

The technology focuses specifically on seamless integration and coordination capabilities. It emphasizes practical implementation in complex production environments.

How does this advancement support human-robot collaboration?

By enabling better communication between systems, it creates safer and more efficient shared workspaces. This improves overall operational coordination.

What industries might benefit most from this technology?

Complex manufacturing sectors like aerospace, automotive, and electronics would see significant advantages. These industries require sophisticated coordination between multiple systems.

About Flexxbotics

Flexxbotics delivers comprehensive solutions for robot-driven manufacturing operations. The company digitalizes production processes with autonomous control capabilities. Flexxbotics technology enables revolutionary applications of robotics in complex manufacturing environments.

LEAVE A COMMENT