Four Foundations for AI-Driven Industrial Automation

Building The Future Of Industrial Automation: Four Foundations For The AI-Driven Era

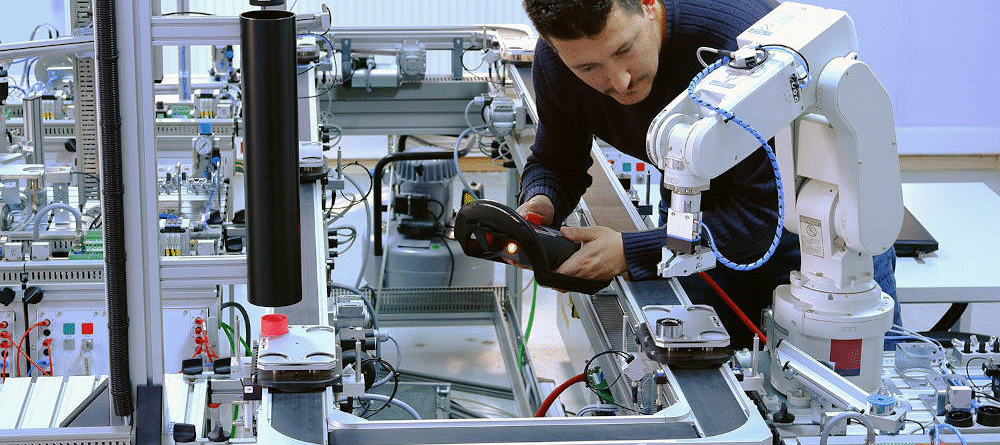

The Strategic Shift in Industrial Automation

Industrial automation faces a critical transformation period. Manufacturers now navigate complex supply chains and rapidly changing markets. Therefore, digital transformation becomes essential for maintaining competitive advantage in today’s industrial landscape.

Data Strategy as Core Investment Priority

Manufacturers prioritize digital capabilities and AI investments. Over 80% of executives recognize smart manufacturing’s crucial role. Moreover, data analytics and cloud computing represent top investment areas for industrial companies.

Software-Defined Automation Architecture

Modern automation requires flexible, software-defined architectures. These systems separate control functions from physical hardware. Consequently, manufacturers achieve faster deployment and easier technology integration across operations.

Industrial Data Fabric Implementation

Data-centric operations demand unified information management. The industrial data fabric connects sensors, machines and enterprise systems. Additionally, this approach ensures proper data contextualization and governance for AI applications.

Advanced Analytics and AI Integration

Companies deploy AI for predictive maintenance and quality control. These systems detect production anomalies and identify root causes. Furthermore, AI tools help address workforce expertise gaps through intelligent guidance systems.

Intrinsic Cybersecurity Frameworks

Modern automation requires robust security foundations. Zero-trust frameworks protect every access point and connection. This approach ensures reliability across field devices, edge computers and cloud platforms.

Executive Leadership and Organizational Change

Successful transformation requires executive commitment and organizational restructuring. Companies must break down traditional operational silos. However, proper implementation delivers significant financial benefits and competitive advantages.

Practical Implementation Scenarios

Rotating equipment monitoring uses AI-powered vibration analysis. Process optimization combines historical data with first principles. Meanwhile, quality control systems automatically detect and correct production deviations.

Frequently Asked Questions

What is software-defined automation?

Software-defined automation separates control functions from physical hardware, creating more flexible and upgradeable systems.

How does industrial data fabric work?

Industrial data fabric connects and contextualizes data from sensors, machines and enterprise systems for AI applications.

What cybersecurity approach suits modern automation?

Zero-trust security frameworks provide protection across all access points, devices and connections in industrial environments.

How does AI address workforce challenges?

AI tools deliver expert guidance and upskilling support to operations staff, helping bridge experience gaps.

What executive support is needed for transformation?

Successful implementation requires top-level championing, organizational restructuring and silo elimination.

LEAVE A COMMENT