Hai Robotics Wins Award for Climbing ASRS

Hai Robotics Secures Prestigious Technology Award for Innovative Climbing ASRS

Industry Recognition for Warehouse Automation Breakthrough

Hai Robotics receives the Technology Excellence Award at PACK EXPO Las Vegas 2025. PMMI honors the HaiPick Climb system in the General Packaging and Processing category. The association describes the technology as game-changing for operational efficiency.

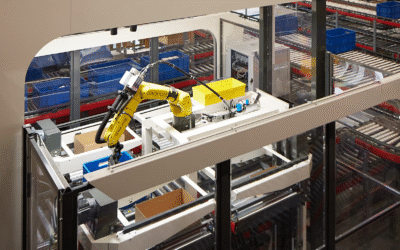

Revolutionary Automated Storage Technology

HaiPick Climb represents a new generation of goods-to-person systems. Compact climbing robots attach to one side of standard warehouse racking. This design eliminates complex installation requirements. Companies can implement automated storage without major facility modifications.

Significant Performance Advantages

The system delivers substantial improvements over traditional automation. Warehouses achieve tote delivery speeds 34% faster than conventional ASRS. Storage footprint reduces by up to 75% while maintaining full functionality. The scalable design supports evolving business requirements.

Leadership Perspective on Innovation

Adrian Stoch, CEO of Americas at Hai Robotics, emphasizes the award validates their customer-focused approach. The technology makes high-efficiency automation accessible to diverse companies. This recognition follows multiple international honors for the HaiPick Climb system.

Global Award Recognition Continues

The PACK EXPO award adds to growing international acclaim. Previous honors include the Excellence in Automation Award in the UK. The system also received dual awards at Modernlog 2025 in Poland. These recognitions highlight global industry approval.

Compatible Automation Solutions

HaiPick Climb integrates with the broader HaiPick Systems portfolio. These modular ASRS solutions support phased implementation strategies. Companies can start with basic automation and expand capabilities gradually. The approach minimizes initial investment while maximizing flexibility.

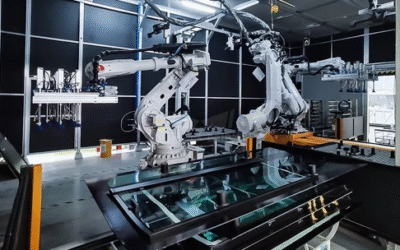

Industry Perspective: Warehouse Automation Evolution

The climbing robot technology represents a significant advancement in storage automation. Traditional ASRS systems require substantial infrastructure investment and complex installation. HaiPick Climb’s simplified approach makes automation accessible to mid-sized operations. This democratization of technology could transform warehouse operations across multiple sectors.

Application Scenario: E-commerce Fulfillment Center

Consider a growing e-commerce company facing space constraints and rising labor costs. Implementing HaiPick Climb enables 75% space reduction while increasing order processing capacity. The system handles peak season volumes without additional staffing. Return on investment typically occurs within 12-18 months.

Frequently Asked Questions

How does HaiPick Climb differ from traditional ASRS?

The system uses climbing robots that mount to existing racking, eliminating need for complex infrastructure and reducing installation time significantly.

What height capabilities does the system offer?

HaiPick Systems support ultra-dense storage reaching over 39 feet high, maximizing vertical space utilization in warehouses.

Can the system be expanded after initial implementation?

Yes, the modular design allows companies to start small and scale operations gradually as business needs evolve.

What accuracy rates does the technology achieve?

The systems maintain 99%+ order pick accuracy while eliminating human travel during order fulfillment processes.

How quickly can warehouses deploy this technology?

Minimal facility preparation requirements enable faster deployment compared to traditional automated storage systems.

Proven Global Implementation Success

Hai Robotics has deployed over 1,700 projects across 40 countries worldwide. The company maintains eight global offices and 60+ partners. This network ensures reliable local support and service for international customers. The track record demonstrates system reliability across diverse operating environments.

LEAVE A COMMENT