Honeywell Automation for Mexico LNG Terminal

Honeywell Automation to Boost Efficiency at New Mexico LNG Terminal

Honeywell will implement its advanced industrial automation and gas pretreatment solutions for the AMIGO LNG export facility in Mexico. This project highlights how modern control systems are transforming energy infrastructure.

Project Overview and Strategic Importance

Honeywell recently announced a major automation partnership for the AMIGO LNG export terminal in Guaymas, Sonora. This joint venture between Epcilon LNG and LNG Alliance will leverage Honeywell’s technology to enhance regional energy development. Moreover, it supports global emission reduction goals while strengthening Mexico’s position in international energy markets.

Modular LNG Pretreatment Advantages

Honeywell’s modular liquefied natural gas pretreatment technology offers significant operational benefits. It removes impurities from natural gas before liquefaction, therefore extending equipment lifespan. This approach also prevents unexpected downtime and enhances overall production reliability. The modular design allows for faster installation and easier future expansion, consequently reducing construction risks.

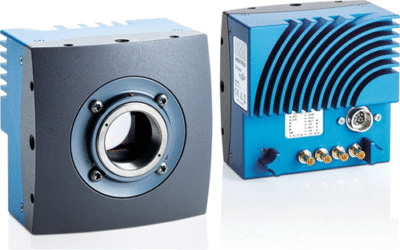

Integrated Control and Safety Systems

The implementation features Honeywell’s Experion distributed control system as part of a comprehensive ICSS solution. This factory automation technology provides enterprise-wide control of the entire facility. Additionally, integrated safety systems monitor for hazardous conditions in real-time. These systems automatically trigger emergency responses, thereby protecting personnel, equipment and the environment.

Accelerating Project Timelines

According to Dr. Muthu Chezhian, CEO of LNG Alliance, Honeywell’s technology is crucial for streamlining construction. The integrated approach helps accelerate project delivery while maintaining high operational standards. Furthermore, modular construction methods enable facilities to reach operational status quicker than traditional approaches.

Alignment with Regional Energy Strategy

The AMIGO LNG terminal directly supports Mexico’s “Plan Sonora” initiative. This strategy aims to establish Sonora as a key hub for global LNG trade. The facility is designed to export up to 7.8 million tonnes per annum when operational in 2028. This project will generate local economic value while advancing cleaner fuel adoption worldwide.

Industry Leadership in LNG Automation

Honeywell brings substantial expertise to this project, having pretreated approximately 40% of the world’s LNG. The company has automated over 80 baseload LNG trains globally. Rajesh Gattupalli of Honeywell UOP emphasized that their integrated approach helps accelerate project timelines while delivering production efficiency benefits.

Application Scenario: LNG Terminal Automation

For similar greenfield LNG projects, consider this approach: Implement modular pretreatment technology to ensure gas specification compliance. Combine this with an integrated DCS for centralized control. Include advanced safety systems for comprehensive protection. This configuration typically reduces commissioning time by 30-40% compared to traditional methods.

Industry Perspective: The Shift to Modular Automation

The energy sector increasingly favors modular automation solutions for greenfield projects. These systems offer faster deployment and reduced field construction hours. However, successful implementation requires careful front-end engineering. We recommend engaging automation partners early in project planning to maximize these benefits.

About the Technology Providers

Honeywell serves global industries through its Industrial Automation and Energy Solutions segments. LNG Alliance develops cutting-edge gas infrastructure across multiple continents. Both companies focus on enabling the global transition to sustainable energy through technological innovation.

Frequently Asked Questions

What makes modular LNG technology advantageous?

Modular construction reduces site labor requirements and weather dependencies. It also enables parallel processing of different project elements, significantly shortening overall schedules.

How does pretreatment impact LNG quality?

Proper pretreatment removes contaminants like water, CO2 and mercury. This ensures the final LNG product meets industry specifications while protecting liquefaction equipment from damage.

What safety standards govern LNG terminal automation?

LNG facilities typically follow IEC 61511 for safety instrumented systems and API standards for process safety. Additionally, most projects implement multiple layers of protection following defense-in-depth principles.

How does this project support energy transition goals?

LNG serves as a bridge fuel during the transition to renewable energy. Modern, efficient LNG facilities like AMIGO help displace higher-emission fuels while maintaining energy security.

What operational benefits does integrated automation provide?

Unified control and safety systems enable better decision-making through centralized data. They also reduce training requirements and simplify maintenance through standardized interfaces.

LEAVE A COMMENT