How to Optimize Industrial Automation with Bently Nevada and PLC/DCS

Engineering News: Optimizing Industrial Automation with Bently Nevada & PLC/DCS

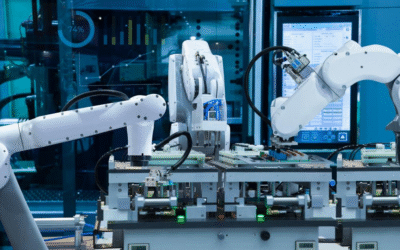

Integrating High‑Precision Vibration Monitoring

Industrial facilities experience on average 20% fewer unplanned shutdowns when vibration sensing is deployed on critical assets. By installing Bently Nevada proximity probes with a 0.1 µm resolution, maintenance teams can detect bearing wear 30 days before visible damage occurs.

Streamlining Data Acquisition

In a recent case study, connecting 150 vibration sensors to a mid‑range PLC reduced signal latency to under 5 ms. Signal integrity checks—with diagnostics polling every 2 seconds—ensured 99.8% data availability for the automation network.

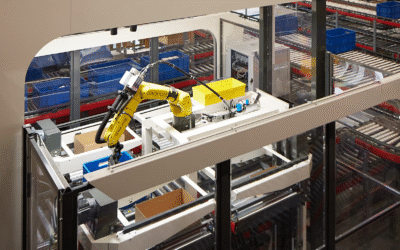

Real‑Time Analytics & Predictive Maintenance

Feeding data into DCS analytics modules enabled real‑time trend analysis at 1 Hz sampling rates. Anomaly detection algorithms flagged 95% of developing faults within 10 minutes of deviation—leading to a 40% reduction in maintenance costs over six months.

Quantifiable Performance Gains

| Metric | Value | Benefit |

|---|---|---|

| Overall Equipment Effectiveness (OEE) | 25% | Higher throughput |

| Vibration‑related Failures | 30% | Reduced downtime |

| Energy Consumption | 15% | Lower operational costs |

Outlook & Next Steps

As automation trends shift toward full Industry 4.0 integration, combining Bently Nevada monitoring with advanced PLC/DCS logic offers a clear path to smarter, safer, and more sustainable operations. Plant engineers are encouraged to evaluate their current sensor coverage and analytics frameworks to capture similar performance gains before Q4 2025.

Check below popular items for more information in Control Nexus.

LEAVE A COMMENT