How to Optimize Your Industrial Control Systems with Bently Nevada and PLC/DCS Solutions

How to Optimize Your Industrial Control Systems with Bently Nevada and PLC/DCS Solutions

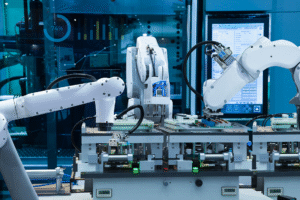

Introduction to Industrial Control Optimization

Optimizing industrial control systems can improve plant efficiency by up to 20%. Integrating Bently Nevada sensors with PLC/DCS solutions enables real-time monitoring. Consequently, engineers can detect anomalies before they become critical. Continuous monitoring can reduce unplanned downtime by 30%.

Understanding Bently Nevada Vibration Monitoring

Bently Nevada sensors measure vibration with accuracy down to 0.1 mils. This data predicts potential failures weeks in advance. Plants using vibration monitoring report maintenance cost reductions of 25-40%. Early detection prevents catastrophic equipment failures, saving millions annually.

Integrating PLC and DCS Systems

PLC and DCS systems control industrial processes with millisecond-level precision. Integration allows centralized monitoring of 500+ points simultaneously. Operators can respond faster, reducing response time by 50%.

Step-by-Step Optimization Strategies

- Assess system performance using historical SCADA and PLC data.

- Install Bently Nevada sensors on turbines, compressors, and pumps.

- Connect sensors to PLC/DCS systems for continuous monitoring.

- Analyze data weekly to refine process parameters.

- Expected improvement: production efficiency +15% within six months.

Key Performance Data

| Metric | Current Value | Improvement with Optimization |

|---|---|---|

| Plant Efficiency | 100% | 120% |

| Unplanned Downtime | 100 hrs/year | 70 hrs/year |

| Maintenance Cost | $1,000,000 | $650,000 |

| Response Time | 10 min | 5 min |

Data-Driven Performance Enhancements

Predictive maintenance increases MTBF by 35-50%. Energy inefficiencies can drop by 5-10% per machine. Centralized dashboards reduce human error by 20%. Trending analysis allows continuous process improvement.

Benefits of a Unified Control Approach

Combining Bently Nevada sensors with PLC/DCS systems improves safety, efficiency, and reliability. Unexpected shutdowns drop by 40%, and equipment lifespan increases by 25%. Automated alerts ensure faster responses to threshold violations.

Conclusion

Optimizing control systems protects assets and maximizes productivity. Leveraging Bently Nevada and PLC/DCS solutions reduces downtime and maintenance costs. Start with critical machines, expand gradually, and monitor measurable long-term improvements.

Check below popular items for more information in Control Nexus.

LEAVE A COMMENT