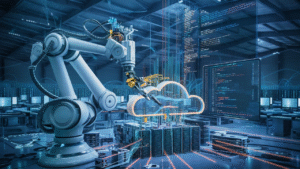

IIoT Predictive Maintenance Solutions

The Transformative Role of IIoT in Predictive Maintenance

Understanding IIoT-Enabled Predictive Maintenance

Industrial Internet of Things revolutionizes maintenance strategies across manufacturing. IIoT connects physical equipment with digital systems. Therefore, it enables real-time monitoring and data-driven maintenance decisions.

Core Technology Components

IIoT predictive maintenance utilizes sensors, connectivity and analytics platforms. These systems collect equipment performance data continuously. Moreover, they identify patterns indicating potential failures before they occur.

Data Collection and Analysis

Vibration sensors, thermal cameras and acoustic monitors gather operational data. Advanced algorithms process this information for anomaly detection. Consequently, maintenance teams receive early warnings about developing issues.

Implementation Benefits

Predictive maintenance reduces unplanned downtime significantly. It extends equipment lifespan and optimizes spare parts inventory. Additionally, it improves workplace safety by preventing catastrophic failures.

Cost Reduction Impact

Companies report 25-30% reduction in maintenance costs with IIoT implementation. They achieve 70-75% fewer breakdowns and 35-45% higher asset availability. These metrics demonstrate clear return on investment.

Integration with Existing Systems

IIoT solutions connect with CMMS and enterprise asset management platforms. This integration creates seamless maintenance workflow automation. Furthermore, it enables historical performance tracking and trend analysis.

Industry-Specific Applications

Manufacturing plants use IIoT for conveyor monitoring and motor analysis. Energy companies monitor turbine performance and pipeline integrity. Each industry applies predictive maintenance according to specific operational needs.

Implementation Challenges

Data security concerns require robust cybersecurity measures. Legacy equipment integration needs additional adapters and sensors. However, these challenges are manageable with proper planning and expertise.

Future Trends and AI Integration

Artificial intelligence enhances IIoT predictive capabilities significantly. Machine learning algorithms improve failure prediction accuracy. Therefore, maintenance becomes increasingly precise and automated.

Expert Perspective: Implementation Strategy

From our industrial automation experience, successful IIoT implementation requires phased approach. Begin with critical equipment monitoring and expand gradually. Ensure proper change management and staff training. This methodology maximizes success while minimizing operational disruption.

Practical Implementation Steps

Start with equipment criticality assessment and sensor deployment. Establish data infrastructure and analytics capabilities. Develop maintenance response protocols and continuous improvement processes. This structured approach ensures sustainable predictive maintenance programs.

Frequently Asked Questions

What is IIoT predictive maintenance?

It uses connected sensors and analytics to predict equipment failures before they occur, enabling proactive maintenance.

What are the main benefits?

Reduced downtime, lower maintenance costs, extended equipment life and improved safety.

What equipment can be monitored?

Motors, pumps, conveyors, turbines and any critical manufacturing assets with measurable performance parameters.

How much does implementation cost?

Costs vary by scale but typically deliver ROI within 12-18 months through reduced downtime and maintenance savings.

What technical skills are required?

Data analytics, sensor technology and maintenance planning expertise, often available through solution providers.

LEAVE A COMMENT