Industrial Automation Trends August September 2025

Industrial Automation Insights: August/September 2025 Technology Review

This month’s industry analysis covers manufacturing equipment maintenance strategies, cybersecurity operational maturity, and modern alarm management systems enhancing operational safety. Subscribe to Automation.com for direct delivery of industrial automation updates.

Process Automation Developments

Open Process Automation systems gain momentum as Automation.com publisher Rick Zabel examines the initiative’s impact on industrial automation. ExxonMobil’s Lighthouse Project demonstrates OPA implementation for resin plant automation near Baton Rouge.

European lithium-ion battery manufacturing advances with €852 million EU investment across six production facilities. This funding supports the Battery Value Chain Enhancement Plan’s €30 billion budget to establish competitive battery production capacity.

IIoT and Digital Transformation

Industrial Foundation Models bridge human expertise and machine efficiency gaps in manufacturing. These specialized AI systems address complexity, precision, and safety requirements beyond conventional artificial intelligence applications.

Artificial intelligence enhances Industrial IoT signal processing through noise reduction, signal enhancement, and anomaly detection. AI technologies promise faster, clearer transmissions while combating interference and disruptions in industrial communications.

Cybersecurity and Safety Solutions

Operational maturity represents the critical missing element in cybersecurity success. Process consistency outweighs cybercriminal sophistication as the primary organizational risk factor when security procedures align with business objectives.

Modern alarm design and management strategies transform basic notifications into intelligent safeguards. Advanced alarm integration reshapes operational safety and efficiency through systematic design approaches and management protocols.

Operations Management Strategies

Digital twin success requires foundational document control before 3D model implementation. Critical barriers include document digitization, data organization, governance frameworks, and operational alignment beyond photorealistic visualization.

Manufacturing tariff impacts highlight workforce skill development needs. Digital manufacturing technologies like additive manufacturing may address tariff challenges while emphasizing skilled labor investment requirements.

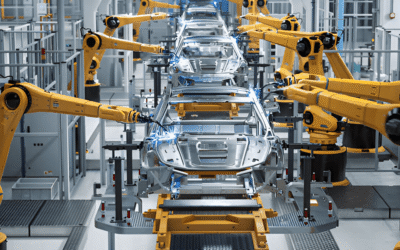

Factory Automation Trends

Modernization versus migration decisions challenge manufacturers managing aging infrastructure. TWI Institute research indicates 80% of unplanned manufacturing downtime links to equipment failure, necessitating strategic upgrade planning.

Automation investment remains steady according to A3 reporting, with robot orders increasing 4.3% and revenue growing 7.5% in 2025’s first half. North American companies ordered 17,635 robots valued at $1.094 billion during this period.

Product Technology Updates

Siemens introduces Virtual Product Expert for CNC programming support, providing on-demand answers to programming and operational questions through interactive expert systems.

ABB’s global NEMA motor solution addresses industrial application requirements worldwide. With HVACR systems consuming 40% of commercial building energy according to U.S. Department of Energy data, the Baldor-Reliance GNEM motor prioritizes energy efficiency.

Industry Perspective

From my analysis of industrial automation trends, the convergence of operational technology and information technology continues accelerating across all sectors. The emphasis on foundational elements like document control for digital twins reflects growing recognition that successful digital transformation requires structural readiness alongside technological implementation.

Implementation Considerations

Organizations should prioritize operational maturity assessment before major cybersecurity investments and evaluate equipment modernization against migration based on lifecycle costs and operational impact rather than solely initial investment requirements.

Frequently Asked Questions

What represents the biggest cybersecurity risk for organizations?

Inconsistent processes and inadequate operational maturity pose greater risks than sophisticated cyber threats according to industry analysis.

How significant is European battery manufacturing investment?

The €852 million allocation to six factories forms part of a comprehensive €30 billion Battery Value Chain Enhancement Plan.

What drives unplanned manufacturing downtime?

Equipment failure causes 80% of unplanned downtime according to TWI Institute research findings.

How is AI transforming industrial signal processing?

Artificial intelligence enhances signal clarity through noise reduction, anomaly detection, and signal enhancement capabilities.

What factors determine modernization versus migration decisions?

Lifecycle costs, operational impact, and existing infrastructure condition guide equipment upgrade strategies.

LEAVE A COMMENT