Industry 4.0 Strategy for Manufacturing Resilience

Industry 4.0: Building Resilient Businesses Through Industrial Automation

The Fourth Industrial Revolution Arrives

Industry 4.0 represents a fundamental shift in manufacturing operations. This transformation merges information technology with operational systems. Consequently, businesses achieve significant productivity gains and competitive advantages.

Strategic Importance of Digital Transformation

Leading companies now implement disruptive technologies across their operations. Artificial intelligence and IoT systems deliver substantial performance improvements. Moreover, regional governments actively support this industrial evolution through national initiatives.

Measurable Business Impact

Industry 4.0 adoption generates remarkable operational benefits. Factories report dramatic productivity increases and faster time-to-market. However, organizations face significant implementation challenges regarding system integration.

Four Foundational Transformation Pillars

Successful digital transformation requires a structured enterprise approach. Companies must align technology with business strategy from the beginning. Additionally, data management and platform selection determine long-term success.

Strategy-Led Implementation Framework

Enterprise-wide strategy prevents isolated innovation projects. Executive leadership must champion the digital transformation vision. Therefore, alignment with core business objectives becomes essential.

Data-Driven Operational Excellence

Manufacturers must treat data as strategic organizational assets. Integrated datasets enable real-time decision-making capabilities. Furthermore, connected systems provide unprecedented operational visibility.

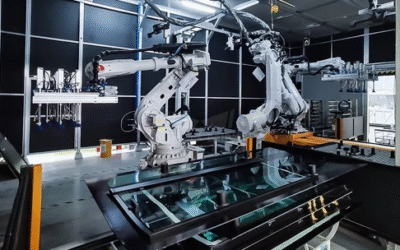

Platform-Centric Technology Integration

Manufacturing execution systems unify diverse automation technologies. These platforms consolidate IoT, cloud and AI capabilities. Consequently, organizations achieve process standardization and collaboration.

Human-Focused Transformation Management

Successful implementation requires new capability models and reskilling programs. Employee engagement ensures sustainable transformation outcomes. Without proper resources, digital initiatives lose momentum.

Practical Implementation Considerations

Manufacturers should evaluate edge versus cloud deployment strategies. Security and data sovereignty requirements influence technology decisions. Meanwhile, legacy system integration remains a critical success factor.

Frequently Asked Questions

What defines Industry 4.0 transformation?

Industry 4.0 integrates IT and OT systems through IoT, AI and advanced automation technologies.

Which regions lead Industry 4.0 adoption?

The META region shows strong commitment through national programs like UAE’s Operation 300 Billion.

What benefits can manufacturers expect?

Companies report up to 160% productivity increases and 90% faster time-to-market.

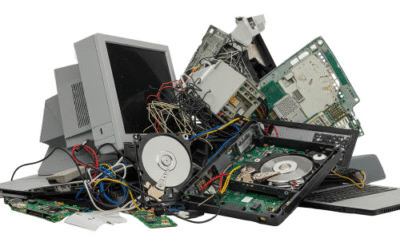

What are key implementation challenges?

Data silos, system integration complexity and IT-OT governance present significant hurdles.

How important is the human element?

Employee reskilling and new capability models are crucial for sustainable transformation.

LEAVE A COMMENT