KUKA Robotics Showcase at Robonumérique Lévis 2025

KUKA Robotics to Showcase Advanced Industrial Automation Solutions at Robonumérique Lévis 2025

Live Demonstrations of Smart Manufacturing Technologies

KUKA Robotics will present cutting-edge automation technologies at Robonumérique Lévis from November 4-5, 2025. The event takes place at Lévis Convention Center in Quebec, Canada. Attendees will experience multiple interactive displays featuring robotic welding systems, autonomous mobile robots, and educational training solutions. Moreover, visitors can explore next-generation iiQKA.OS software and digital engineering tools designed to simplify industrial automation implementation.

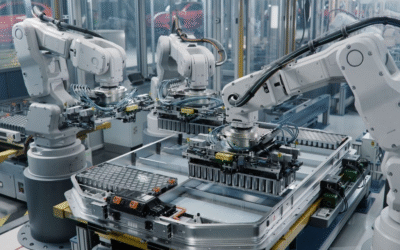

AI-Enhanced Robotic Welding System

KUKA and system partner OptiMach will demonstrate an intelligent welding cell featuring the KR CYBERTECH nano robot. This advanced system integrates real-time vision technology and artificial intelligence. Additionally, it utilizes virtual scanning to analyze components and automatically adjust welding paths. The plug-and-play solution requires no programming expertise or CAD drawings. Therefore, operators of all skill levels can implement automated welding processes effectively.

Autonomous Mobile Robot for Material Handling

The KMP 600P autonomous mobile robot (AMR) will operate continuously in room 101A. This robust system transports materials weighing up to 600 kilograms through constrained production environments. It will navigate around obstacles and interact with fixtures commonly found in manufacturing facilities. Consequently, the AMR demonstrates practical applications for optimizing intralogistics and warehouse automation systems.

Digital Tools and Control Systems

Interactive displays will highlight KUKA’s latest automation technologies including the iiQWorks digital engineering suite. Visitors can examine the ultra-thin KR C5 micro-2 controller and the new iiQKA.OS2 operating system. The arc_cellerate welding cell will also be featured, representing KUKA’s standardized approach to robotic arc welding implementation. These integrated control systems provide comprehensive factory automation solutions for various industrial applications.

Educational Robotics and Training Solutions

KUKA will showcase specialized solutions for robotics education and workforce development. The ready2_educate mobile training cell operates with KUKA.SmartBinPicking software for practical learning. Furthermore, a separate LBR iisy collaborative robot features an education kit for teaching fundamental robotic tasks. These training systems help address the growing skills gap in industrial automation sectors.

Comprehensive Support and Services

All KUKA automation solutions include extensive service and support capabilities. The company provides complete system engineering, simulation services, and training programs. Additionally, readily available spare parts and robot refurbishment services ensure minimal downtime. Customers can access these resources instantly through the my.KUKA.com portal. KUKA maintains multiple corporate offices and integration partner facilities throughout North America for responsive customer support.

Application Scenario: Smart Factory Implementation

Manufacturers seeking to upgrade production facilities can benefit from KUKA’s integrated approach. The demonstrated technologies represent key components of modern smart factories. For instance, the AI-enhanced welding system reduces programming time while improving accuracy. Similarly, autonomous mobile robots optimize material flow between workstations. These industrial automation solutions collectively enhance productivity, quality, and operational flexibility.

Industry Perspective: The Evolution of Automation

Industrial automation continues evolving toward more accessible, interconnected systems. KUKA’s demonstration highlights several key trends, including the integration of AI with robotics and the growing importance of user-friendly interfaces. As automation becomes more prevalent across industries, simplified programming and plug-and-play solutions will likely see increased adoption. These developments make advanced robotics accessible to smaller manufacturers while supporting large-scale industrial operations.

Frequently Asked Questions

What industries benefit from KUKA’s automation solutions?

KUKA serves multiple sectors including automotive, electronics, metals, plastics, consumer goods, food processing, e-commerce, and healthcare. Their systems are particularly relevant for electric vehicle and battery manufacturing applications.

How does the KMP 600P AMR navigate in crowded environments?

The autonomous mobile robot uses advanced sensors and mapping technology to detect and avoid obstacles in real-time. This enables safe operation alongside human workers and existing equipment.

What makes the welding demonstration “smart”?

The system combines artificial intelligence, real-time vision systems, and virtual scanning to automatically adjust welding paths without manual programming, adapting to variations in part positioning.

Are KUKA’s educational robotics solutions suitable for beginners?

Yes, the ready2_educate cell and LBR iisy cobot with education kit are specifically designed for users with varying experience levels, from students to industry professionals seeking skill development.

What support does KUKA provide after system installation?

KUKA offers comprehensive services including training, technical support, spare parts availability, system engineering assistance, and robot refurbishment programs accessible through their online portal.

About KUKA

KUKA is a global automation corporation generating approximately €3.7 billion in annual sales with about 15,000 employees worldwide. Headquartered in Augsburg, Germany, the company delivers intelligent automation solutions including industrial robots, autonomous mobile robots, controllers, software platforms, and cloud-based services. KUKA develops fully networked production systems for various industrial sectors, with particular focus on emerging markets such as electric mobility and battery production.

LEAVE A COMMENT