Manufacturing Supply Chain Transformation

Geopolitical Shifts Drive Manufacturing Supply Chain Overhaul

New research reveals how global instability is forcing manufacturers to rethink operations.

Manufacturers Face Unprecedented Disruption

New research from Revalize reveals significant manufacturing challenges. Geopolitical tensions and trade disputes are reshaping strategies. Companies now aggressively manage supply chain disruptions. They also adjust rising production costs. Additionally, they accelerate digital technology investments.

Key Research Findings Reveal Widespread Impact

The report surveyed 500 business leaders across multiple countries. It highlights three major disruption areas:

- 85% of manufacturers are restructuring supply chains.

- 53% face increased production costs from geopolitical events.

- 50% report higher costs from new tariffs and regulations.

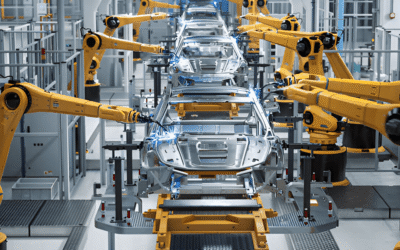

Supply Chain Strategies Undergo Major Transformation

Manufacturers are actively reducing supplier reliance in high-tariff regions. Over half (52%) are diversifying their supply chains. This signals a major shift toward regionalization. Furthermore, one in five international manufacturers exited the U.S. market. The U.S. joins China and Russia as top withdrawal markets.

Digital Transformation Accelerates as Response

Manufacturers are accelerating digital transformation to protect profits. Artificial Intelligence plays a central role in this shift. 51% are adopting AI for supply chain management. Another 50% use AI to optimize operational processes. This represents a broader move toward data-driven efficiency.

Additional Strategic Shifts Emerge

The research reveals several important trends:

- 48% are diversifying supplier bases away from single countries.

- 47% prioritize suppliers with advanced technology capabilities.

- 55% face AI integration challenges from legacy systems.

- 52% plan further supply chain diversification if uncertainty continues.

Leadership Perspective on Manufacturing Challenges

“Manufacturers face intense pressure from global instability,” said Mike Sabin, Revalize CEO. “Shifting trade policies create a complicated playing field. These challenges force difficult operational decisions. Our goal is to provide the tools and technology manufacturers need. This helps them respond with confidence and maintain competitiveness.”

Author’s Analysis: The New Manufacturing Reality

The research clearly indicates a fundamental restructuring of global manufacturing. We’re witnessing a move from efficiency-focused global supply chains to resilience-oriented regional networks. The smartest manufacturers aren’t just reacting to tariffs—they’re rebuilding their operational DNA. Companies that successfully integrate AI with their PLM and CPQ systems will likely emerge strongest, turning geopolitical challenges into competitive advantages through superior agility and data-driven decision making.

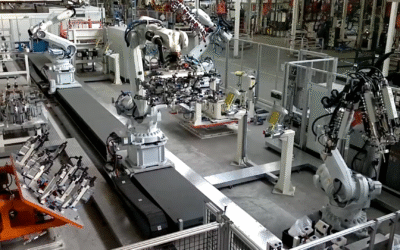

Practical Application: Building a Resilient Supply Chain

Challenge: A mid-sized manufacturer faces 25% cost increases from new tariffs and unreliable suppliers in traditional sourcing regions.

Solution: Implement a dual strategy of supplier diversification across multiple regions while deploying AI-powered inventory management systems.

Outcome: The company reduces single-region dependency from 80% to 35%, cuts inventory costs by 18% through better demand forecasting, and maintains profitability despite global disruptions.

About Revalize

Revalize empowers manufacturing businesses across the value chain. The company provides industry-leading CAD, CPQ and PLM solutions. These tools help manufacturers design, model, develop and sell products more efficiently. Revalize enables a smoother path from concept to revenue generation.

Frequently Asked Questions (FAQs)

What percentage of manufacturers are changing supply chain strategies?

85% of global manufacturers are restructuring their supply chain strategies in response to geopolitical instability.

How are manufacturers using AI to address these challenges?

Over half are adopting AI for supply chain management (51%) and operational process optimization (50%) to improve efficiency and agility.

Which markets are companies exiting due to geopolitical concerns?

The top three markets companies are withdrawing from are Russia (30%), China (22%), and the United States (20%).

What are the main barriers to AI adoption in manufacturing?

55% of organizations report integration challenges caused by unstructured data, siloed systems, and legacy infrastructure.

What long-term strategies are manufacturers considering?

If uncertainty persists, 52% plan further supply chain diversification, while 36% are exploring production localization.

LEAVE A COMMENT