Micro Data Centers Transform Smart Manufacturing

Micro Data Centers: The Hidden Engine of Smart Manufacturing

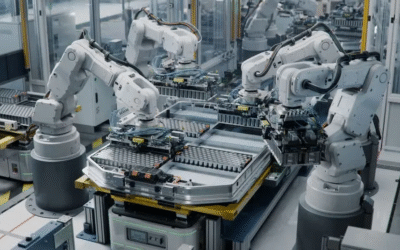

The Data Revolution in Automotive Manufacturing

Modern automotive plants generate enormous data volumes weekly. Some facilities produce up to 5 petabytes of operational data. This information comes from robotics, machine vision and AI systems. Processing delays can cause costly production interruptions. Therefore, real-time data handling becomes critical for success.

The Latency Challenge

Traditional data centers cannot meet manufacturing speed requirements. Transmission delays create operational bottlenecks. Robotics and quality systems need immediate data processing. Even minor latency causes efficiency and safety issues. Consequently, manufacturers seek alternative solutions.

Micro Data Center Advantages

These compact systems integrate computing and networking capabilities. They deploy directly on production floors. This proximity eliminates transmission delays effectively. Modular designs enable rapid installation and scaling. Unlike traditional server rooms, they minimize operational disruption.

Space Optimization Benefits

Manufacturing facilities face severe space constraints. Micro data centers offer compact, flexible footprints. Some units mount on walls or within equipment enclosures. This efficient space usage maximizes production area utilization. The approach supports installation in tight industrial environments.

Operational Resilience Features

Manufacturing downtime costs can reach $10 million hourly. Micro data centers provide built-in redundancy systems. Environmental monitoring and failover capabilities ensure continuous operation. These features maintain production during unexpected outages. Resiliency becomes essential rather than optional.

Security Enhancements

Production data requires robust protection measures. Micro data centers offer physical and network security features. Secure enclosures and access controls prevent unauthorized entry. Isolated network architecture reduces cyber attack risks. This comprehensive approach safeguards sensitive manufacturing information.

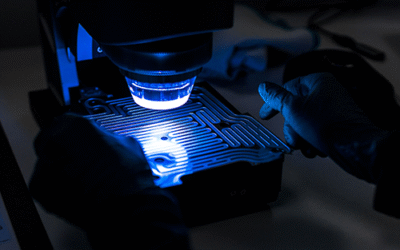

IT-OT Convergence Support

Information technology and operational technology increasingly integrate. Micro data centers bridge these traditionally separate domains. They position computing resources near data generation points. This enables seamless real-time system integration. Successful convergence requires specialized infrastructure support.

Industry Implementation Examples

A packaging company deployed modular data centers within 60 days. This rapid implementation improved energy efficiency significantly. Operational waste reduction increased profitability substantially. Another pharmaceutical company standardized infrastructure across multiple sites. This approach reduced labor costs and installation errors.

Future Manufacturing Requirements

Electric vehicle production demands greater computing capacity. Thirty-four new US battery factories are developing currently. Automated guided vehicles need ultra-low latency connectivity. Private 5G networks require localized computing support. Micro data centers naturally complement these advanced technologies.

Competitive Necessity

Automakers face intense margin pressure currently. Mercedes-Benz experienced 50% profit margin reduction recently. Micro data centers enable predictive maintenance optimization. They help manufacturers meet sustainability requirements. This infrastructure investment provides crucial competitive advantages.

Strategic Implementation Scenario

An automotive manufacturer implements micro data centers across its EV factory. The systems process real-time robot coordination data. Production line latency reduces from minutes to milliseconds. Quality inspection speeds increase by 400%. The company achieves 99.9% operational uptime consequently.

Frequently Asked Questions

What data volumes do modern factories generate?

Some automotive plants produce 5 petabytes weekly from sensors and robotics systems.

How do micro data centers reduce latency?

They process data directly on production floors, eliminating transmission delays to remote facilities.

What security features do they offer?

Secure enclosures, access controls and isolated network architecture protect sensitive production data.

How quickly can manufacturers deploy them?

Some companies become fully operational within 60 days using modular designs.

Why are they essential for EV manufacturing?

They support the high-speed data processing required for battery production and autonomous systems.

LEAVE A COMMENT