NORD Electric Motors Efficiency

NORD Electric Motors: Engineered for Maximum Efficiency and Industrial Reliability

The Critical Role of Electric Motors in Industrial Energy Consumption

Industrial electric drives account for approximately 70% of total energy usage in manufacturing facilities. This creates substantial opportunities for optimization through advanced motor technology. NORD DRIVESYSTEMS addresses this challenge with a comprehensive range of high-efficiency electric motors designed for superior performance and energy conservation.

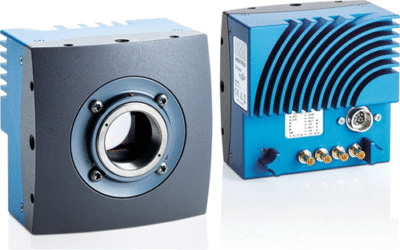

Superior Engineering and Construction Features

NORD manufactures all motors in-house to ensure consistent quality and availability. The motors incorporate advanced insulation systems that provide exceptional moisture resistance and voltage spike protection according to NEMA MG 1 standards. Furthermore, they feature low rotor inertia and high starting torque for demanding applications requiring frequent start-stop cycles. Key construction benefits include dual shaft lip seals, moisture-sealed stator connections, and corrosion-resistant alloys.

Comprehensive Motor Portfolio for Diverse Applications

NORD offers four distinct asynchronous motor lines covering 0.16 to 75 horsepower. This broad range ensures optimal selection for various industrial requirements. The modular design philosophy guarantees compatibility across NORD’s complete gear unit and drive portfolio while maintaining standalone functionality.

Specialized Motors for Hygienic Environments

Smooth-body motors provide ideal solutions for food processing, pharmaceutical, and beverage applications. Their seamless aluminum housings prevent particle accumulation and withstand rigorous wash-down procedures. These motors deliver 0.16 to 1.50 horsepower with IP66 protection and inverter-duty capabilities. Additional options include brakes, thermal protection, and specialized terminal configurations.

IE5+ Synchronous Motor Technology

NORD’s permanent magnet synchronous motors achieve exceptional IE5+ efficiency levels. These units eliminate external magnetic field energy requirements, resulting in superior power density and substantial energy savings. They maintain consistent torque and efficiency across wide speed ranges, even during partial load operation. Both ventilated and smooth-body versions accommodate different cooling requirements and environmental conditions.

Explosion-Protected Motor Solutions

For hazardous environments containing combustible dust or flammable gases, NORD provides certified explosion-proof motors. These units meet rigorous safety standards for Class I and Class II divisions, serving industries from mining to pharmaceutical manufacturing. Available in sizes from 63 to 180 frame with 0.16 to 30 horsepower ratings.

Application-Specific Performance Advantages

NORD motors deliver reliable operation across multiple industries including conveyor systems, agitators, and intralogistics. Their compact design, high gear ratios, and precision-engineered components ensure long service life and reduced maintenance requirements. The consistent dimensional standards enable straightforward upgrades from lower efficiency models.

Technical Innovation and Customization Capabilities

Beyond standard offerings, NORD develops application-specific solutions for unique operational challenges. The company’s engineering expertise supports custom configurations for specialized torque, speed, and environmental requirements. This flexibility, combined with global manufacturing and support, positions NORD as a comprehensive drive technology partner.

Real-World Implementation Scenarios

- Food Processing: Smooth-body motors withstand daily sanitation while maintaining efficiency

- Material Handling: High starting torque enables reliable conveyor operation

- Hazardous Areas: Explosion-proof motors ensure safety in combustible environments

- Energy-Intensive Applications: IE5+ motors reduce electricity consumption significantly

Global Manufacturing and Support Network

With over 4,900 employees and 50 years of industry experience, NORD maintains a worldwide presence through subsidiaries and partners in 80 countries. The extensive distribution network ensures rapid delivery and localized technical support. Manufacturing capabilities cover an impressive range from 88 lb-in to over 2.5 million lb-in torque capacity.

Frequently Asked Questions

What efficiency standards do NORD motors meet?

NORD motors comply with global efficiency regulations, including IE3 premium efficiency and IE5+ ultra-premium levels.

Can NORD motors replace existing units easily?

Yes, IE3 motors maintain identical dimensions to lower efficiency models for straightforward replacement.

What industries benefit most from smooth-body motors?

Food processing, pharmaceuticals, and beverage production where hygienic cleaning is essential.

How do IE5+ motors achieve higher efficiency?

Permanent magnet technology eliminates excitation losses and maintains efficiency across speed ranges.

What explosion protection certifications are available?

NORD offers Class I Division 2 for gases and Class II Division 2 for dust environments.

LEAVE A COMMENT