PLC Automation for Wastewater Plants

Smart Control: How PLCs are Driving Efficiency in Wastewater Treatment

Wastewater treatment plants are vital for community health. Many are now upgrading their operations with industrial automation. Programmable Logic Controllers (PLCs) are at the heart of this transformation. They deliver remarkable gains in efficiency and reliability.

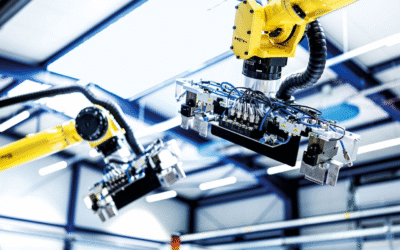

PLCs: The Brain of the Modern Treatment Plant

Think of a PLC as the facility’s central command center. It continuously gathers data from sensors throughout the process. Therefore, it can make intelligent decisions in real-time. This replaces outdated manual control methods.

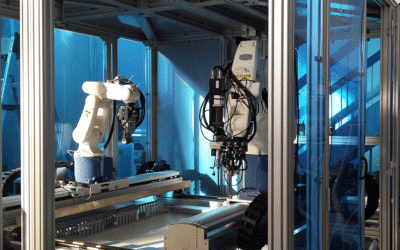

Automating Complex Treatment Sequences

PLCs expertly manage intricate treatment sequences. They automatically control pumps, valves, and blowers. For instance, they adjust chemical dosing based on incoming water quality. This automation ensures consistent processing day and night.

Slashing Energy Costs with Smart Control

Energy consumption is a top expense for these facilities. PLCs tackle this directly through optimized control strategies. They can cycle high-energy equipment like aeration blowers. Consequently, plants significantly reduce their power bills.

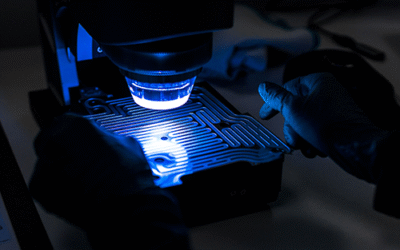

Guaranteeing Consistent Regulatory Compliance

Meeting environmental standards is non-negotiable. PLCs monitor key parameters like pH and chlorine levels. They make immediate adjustments to maintain perfect balance. This proactive approach ensures effluent always meets regulations.

From Data to Actionable Insights

Modern control systems are powerful data historians. They log every aspect of plant performance. Operators can then analyze trends and predict maintenance needs. This data-driven approach prevents unexpected equipment failures.

Proactive Maintenance for Maximum Uptime

Unexpected downtime is incredibly costly. PLCs provide early warnings for potential pump or motor failures. Maintenance teams can schedule repairs during planned outages. This strategy dramatically improves overall asset reliability.

The Future: PLCs Meet IIoT and Cloud Computing

The next evolution involves integrating PLCs with the Industrial Internet of Things (IIoT). Data from Siemens or Rockwell Automation PLCs can feed cloud platforms. This enables remote monitoring and advanced analytics. We believe this will become the new industry standard.

Real-World Application: A Plant Upgrade Scenario

Consider a plant struggling with high energy costs and compliance issues. By installing a new PLC-based control system, they automate their aeration tanks. The system uses dissolved oxygen sensors to optimize blower speed. As a result, the plant cuts energy use by 20% and consistently passes audits.

Frequently Asked Questions (FAQ)

What is the main benefit of using a PLC in wastewater treatment?

The primary benefit is vastly improved operational efficiency. PLCs automate complex processes and reduce manual labor.

How do PLCs help save energy?

They save energy by intelligently controlling motors and blowers. The system runs equipment only when necessary.

Can PLC systems be retrofitted into older plants?

Yes, many plants successfully upgrade their old relay systems. This modernization boosts performance cost-effectively.

What is the difference between a PLC and a DCS?

A PLC is great for discrete control and high-speed logic. A DCS often handles larger, more complex process loops.

How do PLCs improve water quality?

They constantly monitor and adjust chemical feed rates. This ensures the treated water meets strict quality standards.

LEAVE A COMMENT