PLC Evolution in Industry 4.0

The Future of PLCs in the Age of Industry 4.0

Programmable Logic Controllers are not becoming obsolete. They are instead evolving into more intelligent components. Industry 4.0 demands connectivity and data-driven operations. Modern PLCs are perfectly positioned to meet these new challenges. They remain the reliable workhorse of industrial automation.

From Isolated Control to Networked Intelligence

Traditional PLCs operated as isolated islands of automation. Now, they function as integrated nodes in a smart network. They seamlessly communicate with SCADA and MES layers. This connectivity enables a holistic view of the entire operation. Therefore, data flows freely from the sensor to the cloud.

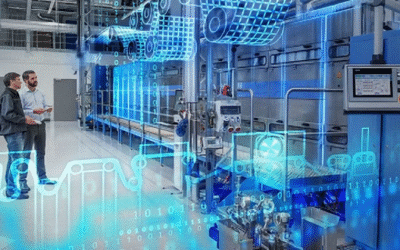

The Convergence of PLC and IT Systems

The line between operational technology and information technology is blurring. Modern PLCs from vendors like Siemens and Rockwell Automation support IT-friendly protocols. They can securely transmit data to enterprise databases. This convergence allows for unprecedented operational insights. Managers can make decisions based on real-time production data.

Enhanced Capabilities with Embedded Analytics

Next-generation PLCs possess more powerful computing cores. They can now perform edge analytics directly on the controller. This means they can detect anomalies and predict faults locally. Consequently, they enable faster response times and reduce cloud data costs. This is a significant step towards decentralized intelligence.

Cybersecurity as a Fundamental Feature

Increased connectivity brings heightened security risks. Future PLC designs prioritize cybersecurity from the ground up. They incorporate features like secure boot and user role management. Plant engineers must implement these protections rigorously. A secure controller is now a non-negotiable requirement for any modern facility.

Simplifying Integration and Maintenance

Industry 4.0 emphasizes interoperability and ease of use. PLC programming is becoming more standardized with languages like IEC 61131-3. Furthermore, tools for virtual commissioning are maturing rapidly. This allows engineers to test and debug logic offline. The result is a much faster and more reliable deployment process.

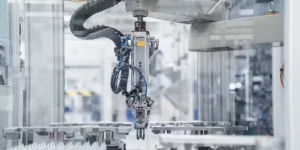

Application Scenario: Predictive Maintenance

Imagine a PLC monitoring a critical pump. It analyzes vibration and current draw data in real-time. The controller then identifies a pattern indicating impending bearing failure. It automatically creates a maintenance work order. This proactive approach prevents costly unplanned downtime and extends asset life.

Frequently Asked Questions (FAQ)

Will cloud computing replace PLCs?

No, cloud and PLCs will coexist. PLCs handle real-time control reliably, while the cloud offers vast storage and deep analysis.

How are PLCs adapting to IIoT?

They are gaining native support for IIoT protocols like MQTT and OPC UA. This allows direct communication with other smart devices and platforms.

What skills are needed for future PLC programming?

Engineers will need knowledge of network security, data analytics, and IT integration alongside traditional ladder logic and structured text.

Are software-based PLCs a threat to hardware PLCs?

Software PLCs offer flexibility for certain applications. However, hardware PLCs will dominate where rugged reliability and deterministic control are critical.

How does AI integrate with PLC systems?

AI models often run on an edge device or in the cloud. The PLC provides the real-time process data and executes the AI-generated control commands.

LEAVE A COMMENT