SCADA System Modernization Case Study

Heritage Petroleum Modernizes SCADA Infrastructure with Skkynet DataHub Solution

Project Background and Operational Challenge

Following the 2018 restructuring of Trinidad and Tobago’s state oil company Petrotrin, Heritage Petroleum Company inherited an aging SCADA system requiring modernization. The newly formed exploration and production company needed to digitize operations and implement IoT technologies across its onshore and offshore facilities.

Strategic Implementation Partnership

Heritage engaged TOSL Automation and Technology Limited (TATL) to lead the upgrade initiative. The project team collaborated with Costa Rican firms Incentro S.A. for AVEVA software expertise and Soati for system integration support, creating an international consortium of technical specialists.

Two-Phase Modernization Approach

The upgrade strategy involved two distinct phases. Phase one focused on revitalizing the existing SCADA infrastructure using AVEVA InTouch, Historian and Web Client platforms. Phase two expanded the scope to incorporate remote sensor monitoring through MQTT protocol integration.

Cost-Effective Asset Utilization

“The original approach involved complete system replacement,” explained Keone Jackman, TATL General Manager. “We proposed upgrading existing SCADA components instead, saving significant resources while achieving production visibility and ERP integration objectives.”

MQTT Integration Challenge

The expansion phase revealed a critical need for MQTT broker capability to handle data from electrical substations, compression monitoring systems, and remote sensors. This requirement led the team to Skkynet’s DataHub software, selected for its MQTT support and AVEVA compatibility.

Technical Implementation Strategy

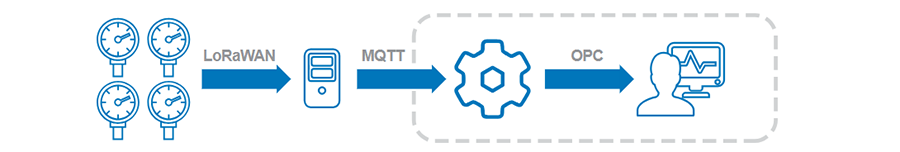

The team deployed HiberHilo sensors across offshore production facilities, transmitting data via LoRaWAN networks. DataHub instances functioned as MQTT clients, collecting and integrating data streams before forwarding information via OPC to AVEVA applications.

Protocol Conversion Complexity

“This project required significant customization,” noted Aneesa Mohammed, TATL ICE Engineer. “We processed multiple JSON formats from various sensors, created custom tags in InTouch, and developed specialized display screens. Skkynet’s support team assisted with custom JSON conversion scripts.”

Redundancy and System Resilience

The implementation encountered unexpected challenges with HiberHilo server parallel connectivity. The team developed a quality-of-service monitoring solution using DataHub scripts to assess dual MQTT server paths and automatically switch between systems when signal quality degraded.

Operational Benefits Realized

The upgraded system delivered modernized dashboards, enhanced availability, improved user experience, and strengthened security. MQTT integration enabled advanced analytics, better alarm management, third-party application connectivity, and scalable device expansion capabilities.

Significant Cost Avoidance

Reusing existing communication infrastructure generated substantial savings. “Preserving current systems saved approximately six months of implementation time and associated costs,” Jackman confirmed.

Knowledge Transfer and Support Excellence

Skkynet provided comprehensive training for Heritage’s IT team, focusing on DataHub scripting and device integration. “The support team consistently delivered script modifications within 24-48 hours and remained available for troubleshooting,” Mohammed acknowledged.

Future Expansion Planning

Heritage plans to extend the system to onshore business units, integrating additional sensors and InTouch monitoring screens. TATL remains engaged to support future DataHub implementations and scripting requirements.

Industrial Automation Perspective

This case study demonstrates how legacy SCADA systems can be modernized cost-effectively through strategic software integration. The approach showcases the growing importance of MQTT protocol in industrial IoT applications and the value of flexible data brokerage solutions in complex automation environments.

About Skkynet

Skkynet specializes in real-time data connectivity solutions for industrial automation and IIoT applications. Their DataHub product line enables secure, real-time data exchange for plant operations and cloud-based systems, supporting Industry 4.0 initiatives across multiple sectors.

Frequently Asked Questions

What was the primary challenge Heritage Petroleum faced?

Heritage inherited an outdated SCADA system requiring modernization to support digital transformation and IoT integration across offshore and onshore operations.

How did Skkynet’s DataHub software contribute to the solution?

DataHub provided MQTT broker functionality, protocol conversion capabilities, and seamless integration with AVEVA SCADA systems while handling multiple data formats.

What were the key benefits achieved?

The project delivered modernized interfaces, enhanced system availability, improved analytics, and scalable architecture for future expansion while preserving existing infrastructure investments.

How significant were the cost savings?

Reusing existing communication infrastructure saved approximately six months of implementation time and associated replacement costs.

What support services were provided?

Skkynet delivered comprehensive knowledge transfer, custom scripting support with 24-48 hour turnaround, and ongoing troubleshooting assistance throughout the project lifecycle.

LEAVE A COMMENT