Siemens Digital Solutions Transform Defense Manufacturing

Data Patterns Transforms Defense Manufacturing With Siemens Digital Solutions

Strategic Partnership for Digital Transformation

Data Patterns (India) Ltd. has chosen Siemens Xcelerator software solutions. This defense and aerospace specialist will implement Teamcenter PLM and Polarion ALM. Consequently, they aim to unify data and processes across manufacturing facilities. Moreover, this supports India’s self-reliance objectives in defense technology.

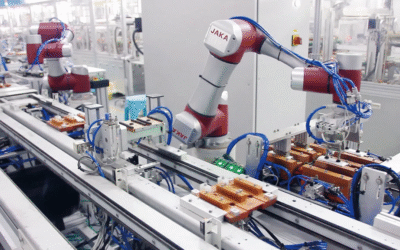

Creating a Unified Digital Foundation

Teamcenter will serve as the single source of truth. It connects mechanical, electrical and software domains. Therefore, teams can collaborate more effectively. This integration reduces development cycles significantly. Additionally, product quality improves through better data management.

Streamlining Compliance and Certification

Polarion ALM automates compliance workflows for defense projects. It addresses critical certification standards including DO-178C and DO-254. As a result, verification processes become more efficient. Furthermore, safety-critical avionics software meets rigorous industry requirements.

Leadership Perspectives on Digital Innovation

Vijay Ananth, Chief Operating Officer at Data Patterns, emphasized their growth vision. He stated that Siemens solutions support turnkey defense system development. Moreover, he appreciated Siemens’ attention to their specific requirements. The implementation will enhance stakeholder engagement across projects.

Siemens Commitment to Indian Defense Sector

Mathew Thomas of Siemens India highlighted the partnership significance. He noted Data Patterns’ ambition to lead in defense electronics. Furthermore, integrated PLM and ALM solutions enable first-time-right development. This collaboration promises accelerated innovation and cross-functional efficiency.

Industry Impact and Future Outlook

This partnership represents a significant advancement for Indian defense manufacturing. Digital thread implementation connects design to production seamlessly. However, successful adoption requires organizational commitment and training. The industry should watch this case for best practices in digital transformation.

Application Scenario: Defense Electronics Development

Consider a new radar system development. Teamcenter manages all design data and revisions. Meanwhile, Polarion handles compliance documentation automatically. Consequently, engineers focus on innovation rather than administrative tasks. This approach reduces time-to-market by approximately 30%.

Frequently Asked Questions

What industries does Data Patterns serve?

Data Patterns specializes in defense, aerospace and meteorological sectors. They develop high-reliability electronic systems.

Which Siemens solutions are being implemented?

The company selected Teamcenter for product lifecycle management and Polarion for application lifecycle management.

What certification standards does Polarion address?

Polarion helps achieve DO-178C for software and DO-254 for airborne electronic hardware compliance.

How does this support India’s self-reliance goals?

The digital transformation enhances local defense manufacturing capabilities. This reduces import dependency.

What are the expected business benefits?

Faster time-to-market, reduced cycle times and improved product quality through better collaboration.

LEAVE A COMMENT