Tronics MEMS Vibration Sensors for Machine Health

TDK’s Tronics Expands into Industrial Vibration Monitoring with Advanced MEMS Sensors

Strategic Market Entry

TDK Corporation reveals its subsidiary Tronics Microsystems is strategically entering the machine health monitoring sector. Consequently, the company introduces new vibration sensor solutions for process and asset monitoring. This expansion marks a crucial evolution point for the MEMS specialist. Moreover, it demonstrates TDK’s commitment to industrial digital transformation across multiple sectors.

Building on MEMS Expertise

Tronics brings over twenty years of specialized MEMS experience. The company previously focused on high-performance inertial sensors for aerospace and energy applications. Therefore, this vibration monitoring expansion represents a natural progression. The company leverages its extensive MEMS research and manufacturing background. Additionally, it maintains its reputation for precision and reliability in industrial applications.

Corporate Mission and Vision

Tronics maintains a clear mission to provide MEMS sensor solutions for motion sensing and asset monitoring. The company serves transportation, energy, and industrial sectors. Its vision supports digital transformation through advanced inertial and vibration sensors. Furthermore, Tronics aims to enhance operational efficiency across industrial automation systems.

Industrial Evolution and Innovation

Industrial sectors increasingly adopt IoT technologies and smart monitoring systems. As a result, demand grows for advanced vibration spectrum analysis capabilities. Tronics responds by engineering specialized MEMS solutions rather than using standard accelerometers. The company CEO emphasizes their custom engineering approach meets condition-based monitoring requirements. Moreover, their solutions maintain the same precision standards as their established inertial products.

Product Development Progress

Tronics currently finalizes its first-generation vibration sensor platform. These solutions enable highly accurate quality control systems. Additionally, they support predictive maintenance applications in industrial automation. The technology helps prevent equipment failures through continuous monitoring. Therefore, manufacturers can reduce downtime and maintenance costs significantly.

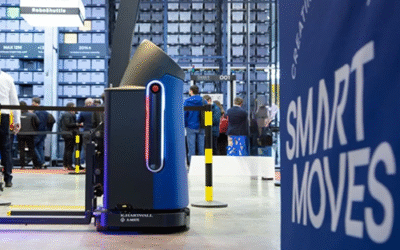

Industry Event Demonstrations

TDK will showcase this innovative technology at major industrial exhibitions. The electronica India event occurs September 17-19 in Bengaluru. Furthermore, sps–Expo runs November 25-27 in Nuremberg. Visitors can experience live demonstrations at TDK booths. The Innovation Marketing Manager will present how these smart IoT sensors transform machine health monitoring.

Corporate Background: TDK Corporation

TDK Corporation represents a global electronics technology leader headquartered in Tokyo. The company operates with the philosophy “In Everything, Better.” For over nine decades, TDK has driven technological innovation from ferrite cores to modern sensors. The company now powers diverse applications from industrial systems to electric vehicles. Moreover, TDK maintains a startup mentality through its Venture Spirit approach.

About Tronics Microsystems

Tronics Microsystems operates as a TDK Group Company specializing in MEMS solutions. The company provides accelerometers, gyroscopes, and vibration sensors. Additionally, it offers MEMS foundry services for specialized applications. Founded in 1997, Tronics employs approximately 100 professionals in France. The facility maintains EN 9100 certification for aerospace-quality manufacturing standards.

Practical Application Scenarios

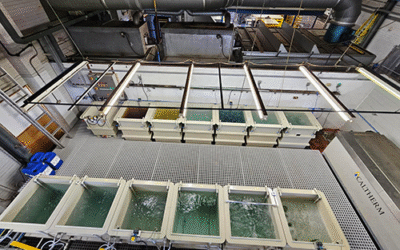

Industrial facilities can implement these vibration sensors for critical equipment monitoring. For example, manufacturers can monitor motor vibrations in production lines. This enables early detection of bearing wear or imbalance issues. Additionally, energy companies can monitor turbine health in power generation facilities. The sensors provide continuous data for predictive maintenance algorithms. Therefore, companies can schedule maintenance before catastrophic failures occur.

Industry Perspective

The industrial automation market increasingly values predictive maintenance capabilities. Vibration monitoring represents a crucial component of comprehensive asset management strategies. Tronics enters this market with substantial MEMS expertise. However, they face established competition from traditional vibration monitoring specialists. Their success will depend on demonstrating superior accuracy and reliability in demanding industrial environments.

Frequently Asked Questions

What applications suit Tronics’ new vibration sensors?

These sensors excel in industrial automation applications requiring precise vibration monitoring. They help predict maintenance needs for motors, pumps, and rotating machinery.

How do these sensors differ from standard accelerometers?

Tronics engineered these specifically for condition monitoring rather than using basic accelerometers. They offer enhanced precision and reliability for industrial environments.

Where can engineers see demonstrations?

TDK will showcase the technology at electronica India and sps–Expo. Live demonstrations will illustrate practical applications.

What industries benefit most from this technology?

Manufacturing, energy, and transportation sectors gain significant advantages. Any industry using critical rotating machinery can implement predictive maintenance.

When will these sensors become commercially available?

Tronics is completing first-generation development now. Commercial availability should follow upcoming demonstrations and testing phases.

LEAVE A COMMENT