Unified Device Integration Roadmap Released

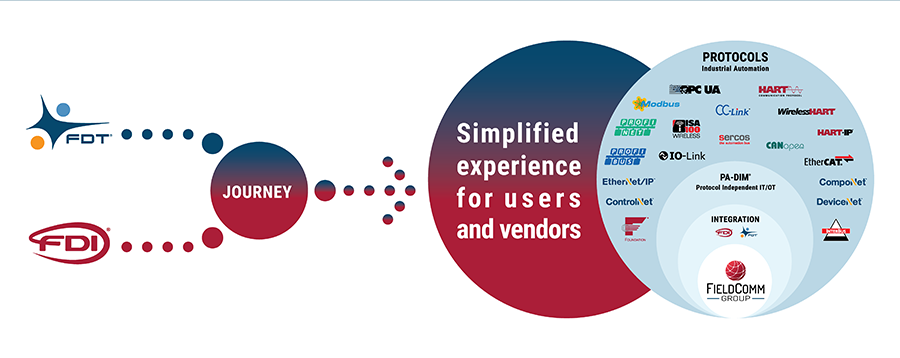

Industry Unites on Common Path for Device Integration with New FDI Roadmap

Major automation standards bodies have agreed on a unified timeline for a crucial device integration specification. This collaboration promises to simplify how industrial devices communicate across different automation platforms.

Accelerating Standardization After Merger

Following the 2024 combination of FieldComm Group and FDT Group assets, development of a unified standard has gained significant momentum. The Strategic Integration Committee, comprising leading automation suppliers and standards organizations, has established clear deadlines for delivering the updated Field Device Integration (FDI) Specification.

Key Advancements in Device Integration

The updated FDI Specification introduces several critical improvements for industrial automation:

Cybersecurity Compliance

The specification incorporates requirements of the Cyber Resilience Act, addressing growing concerns about industrial network security.

Cross-Platform Unity

For the first time, a single standard will serve both process and factory automation environments, eliminating compatibility barriers.

Legacy System Support

Organizations can modernize their operations without replacing existing infrastructure, protecting previous investments.

Enhanced Connectivity

Real-time OT/IT connectivity through a common information model (PA-DIM) enables seamless data flow between operational and information technologies.

Clear Implementation Timeline

The industry now has a definitive schedule for adopting the unified standard:

2026

The updated FDI Specification will be released to vendors and developers.

2027

Development tools become available, enabling product development.

2029

FDI-enabled systems and devices reach the market, beginning widespread adoption.

Industry Leaders Endorse Unified Approach

Steve Biegacki, Chair of the Strategic Integration Committee, emphasized the importance of this initiative. “Today’s industrial systems are more complex than ever,” he noted. “Our goal is to deliver a unified solution that enhances data interoperability while supporting innovative features for modern manufacturing.”

Standards organizations including OPC Foundation, ODVA, and PROFIBUS & PROFINET International have publicly supported the harmonization effort. Their collective endorsement signals strong industry-wide commitment to resolving long-standing integration challenges.

Author’s Perspective: The End of Automation Silos

This unification represents a watershed moment for industrial automation. For decades, factories have struggled with incompatible devices and proprietary systems that created operational silos. The merged FDI/FDT approach finally addresses this fundamental challenge.

From practical experience, the protocol tunneling capability (nested communications) may prove most valuable. This feature allows different communication protocols to operate through a unified interface, dramatically simplifying system architecture and maintenance procedures.

Practical Benefits for Industrial Operations

Reduced Engineering Costs

A single integration standard means engineers need only master one technology stack for device configuration and maintenance.

Extended Equipment Lifecycle

Legacy system support ensures existing automation investments continue providing value while enabling gradual modernization.

Enhanced Cybersecurity

Built-in compliance with the Cyber Resilience Act helps organizations meet evolving regulatory requirements without additional engineering effort.

Frequently Asked Questions

What problem does the unified FDI specification solve?

It eliminates the need for different integration technologies in process and factory automation, creating a single standard for all device types.

How does this affect existing automation systems?

The specification includes backward compatibility, allowing organizations to maintain existing systems while gradually adopting the new standard.

When will end users see tangible benefits?

Initial benefits will appear in 2027-2028 as development tools mature, with widespread impact expected by 2029 when compliant devices reach volume production.

Which communication protocols are supported?

The standard supports major protocols including HART, Fieldbus, PROFINET, EtherNet/IP and others through protocol tunneling capabilities.

How does this relate to Industry 4.0 initiatives?

The unified specification provides the device-level integration foundation necessary for implementing comprehensive Industry 4.0 and IIoT strategies.

Strategic Importance for Digital Transformation

This standards unification arrives at a critical juncture for industrial digitalization. As companies pursue smarter manufacturing initiatives, consistent device integration becomes essential for leveraging industrial data. The harmonized FDI/FDT approach provides the missing link between field devices and enterprise systems, enabling the seamless data flow required for advanced analytics and autonomous operations.

About FieldComm Group

FieldComm Group is a global standards organization dedicated to advancing industrial automation through open, interoperable technologies. The organization brings together end users, manufacturers, and service providers to promote standards for industrial communication and device integration across all manufacturing sectors.

LEAVE A COMMENT