Universal Robots Debut New Cobot at FABTECH 2025

Universal Robots Revolutionizes Fabrication with Advanced Cobot Solutions at FABTECH 2025

Collaborative Robotics Transforms Metal Fabrication

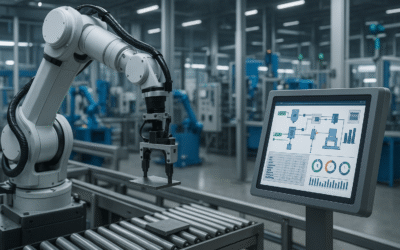

NOVI, Michigan, Sept. 3, 2025 – Universal Robots (UR), the collaborative robotics market leader, will showcase groundbreaking automation solutions at FABTECH 2025 in Chicago. The event, scheduled for September 8-11, will feature advanced cobot applications for welding, cutting, and finishing operations. These innovations demonstrate how collaborative robotics continue to evolve fabrication processes across multiple industries.

Industry Leadership in Cobot Welding Evolution

Jean-Pierre Hathout, President of Universal Robots, emphasized the rapid advancement in cobot welding technology. “Cobot welding continues evolving at remarkable speed,” Hathout stated. “Eight years ago, we introduced North America’s first cobot welder at FABTECH 2017. Today, advanced robot control features and partner innovations enable applications previously considered impossible.” The event provides an ideal platform to experience how UR robots transform complete fabrication workflows.

New Robot Platform Sets Performance Benchmarks

FABTECH attendees will witness the global debut of a new UR robot engineered specifically for demanding welding applications. This model delivers exceptional reach, stability, and precision for challenging fabrication tasks. “Designed to excel under pressure, this robot sets new benchmarks for industry capabilities,” Hathout explained. The new robot will appear in UR’s booth #B13045 and partner booths including Hirebotics, THG Automation, and Vectis Automation.

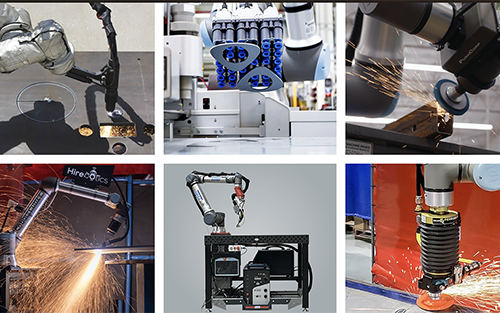

Automated Plasma Cutting Enhances Welding Efficiency

Automated plasma cutting represents one of the fastest-growing cobot applications due to significant welding efficiency improvements. Traditional manual cutting often produces inconsistent results that complicate subsequent welding processes. Conversely, robotic cutting delivers precisely prepared parts ready for seamless automated welding. This integrated approach streamlines production while maintaining consistent quality standards.

Partner Innovations Drive Cutting-Edge Solutions

Hirebotics demonstrates their Cobot Cutter in booth #B13051, providing fast, precise cuts on various metals while eliminating manual rework. The company also introduces multipass welding, through-the-arc seam tracking, and AI-powered weld setting recommendations. Meanwhile, Vectis Automation advances the field with their Shape Tool in booth #B13031, enabling complex shape cutting on curved surfaces. Their ClarityData Insight Dashboard captures production metrics for optimized program efficiency.

Laser Welding Reaches Mainstream Adoption

Cobot laser welding now achieves mainstream acceptance through advances in control software, safety engineering, and fiber laser affordability. THG Automation’s URW-2LF Collaborative Laser Welding System in booth #B13053 combines UR robotics with IPG fiber laser technology. This system delivers cleaner, faster welds with minimal heat distortion while incorporating laser-based pre-cleaning and discoloration removal for superior finish quality.

Advanced Finishing and Material Handling Solutions

Finishing and grinding applications take center stage at UR’s booth with multiple technology demonstrations. PushCorp pairs a UR30 robot with servo spindle and active force device technology for automated, uniform surface finishing. Ferrobotics demonstrates their cobot active force control system designed for heavier payload applications. The solution supports up to 15 different finishing tools while providing intuitive operation for both beginners and advanced users.

Intelligent Material Handling Innovations

Material handling remains essential in fabrication workflows, encompassing machine tending, picking, stacking, and palletizing operations. UR’s fastest robot, the UR15, will feature Schmalz’s new FMG matrix area gripper with innovative air-saving technology. This system reduces compressed air consumption by up to 80%, making it ideal for sheet metal production environments where energy efficiency matters.

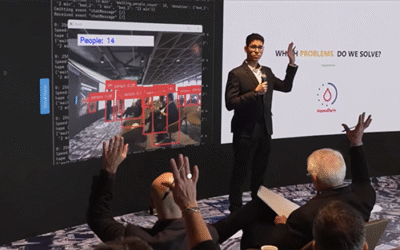

Industry Expertise Through Educational Sessions

FABTECH attendees can gain valuable insights from Will Healy III, Teradyne Robotics’ global industry leader for metal fabrication. The conference schedule includes multiple technical presentations covering automation implementation, AI integration, and business transformation through robotics. These sessions provide practical guidance for fabricators at various stages of automation adoption.

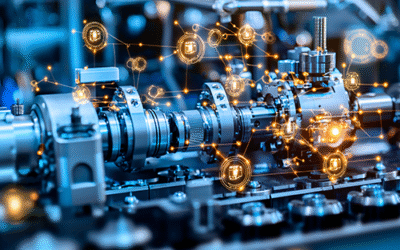

Technical Perspective: The Cobot Revolution in Fabrication

From my professional assessment, Universal Robots’ FABTECH demonstrations highlight a crucial industry shift toward accessible, high-performance automation. The integration of AI-driven path optimization, through-the-arc sensing, and active force control represents the next evolution in smart manufacturing. These technologies democratize advanced fabrication capabilities for small and medium enterprises while pushing performance boundaries for large manufacturers. The emphasis on energy-efficient components and simplified programming interfaces addresses key adoption barriers in the metal fabrication sector.

Application Scenario: Integrated Fabrication Cell

Modern cobot applications demonstrate how integrated fabrication cells transform production workflows. A typical cell might incorporate plasma cutting for part preparation, laser welding for assembly, and automated finishing for final treatment. Such integration reduces handling time between processes while maintaining consistent quality standards. Companies implementing similar solutions typically report 40-60% reduction in processing time and 30-50% improvement in material utilization efficiency.

Frequently Asked Questions

What advantages do cobots offer over traditional industrial robots in fabrication?

Cobots provide simpler programming, faster deployment, and safer operation alongside human workers. They require less specialized expertise while offering flexibility for high-mix, low-volume production environments.

How does automated plasma cutting improve welding quality?

Robotic cutting delivers consistent edge preparation and dimensional accuracy. This consistency enables seamless automated welding with reduced defects and minimal rework requirements.

What safety measures enable cobot laser welding?

Advanced safety systems including protective housings, light curtains, and real-time monitoring ensure safe laser operation. These integrated safety solutions maintain collaborative operation while meeting stringent laser safety standards.

How do force control systems enhance finishing applications?

Active force control maintains consistent pressure during grinding and polishing operations. This consistency ensures uniform surface treatment while accommodating part variations and tool wear.

What ROI can fabricators expect from cobot implementation?

Typical ROI periods range from 6-18 months depending on application complexity and production volume. Benefits include reduced labor costs, improved quality consistency, and increased equipment utilization rates.

LEAVE A COMMENT