Valmet Rebuilds Sappi Paper Machine for Packaging Shift

Sappi North America Transitions to Packaging with Valmet’s Advanced Paper Machine Technology

Successful Machine Rebuild Marks Strategic Shift

Sappi North America and Valmet have celebrated the successful startup of the rebuilt Paper Machine 2 at Maine’s Somerset facility. The machine produced its first roll of solid bleached sulphate board in May 2025. This achievement represents a crucial milestone in Sappi’s strategic transition toward packaging grades.

Partnership Drives Project Success

Despite ongoing optimization work, the early production of commercial-grade board demonstrates effective collaboration. Kirk Ross, Sappi’s VP of Manufacturing, praised Valmet’s technical expertise and project execution capabilities. He emphasized their ability to navigate complex requirements and global supply chain challenges.

Building on Previous Success

This project, named “Project Elevate,” follows the successful PM1 rebuild completed in 2018. Valmet’s Tuomo Rämö highlighted the sustainable conversion that transformed PM2 into a modern board machine. He credited the achievement to excellent teamwork between Sappi’s Somerset team and Valmet specialists.

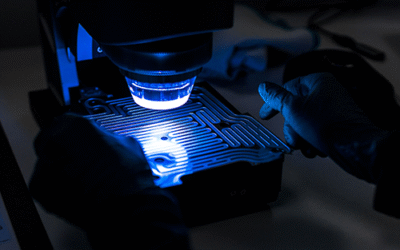

Comprehensive Technical Upgrade

Valmet’s delivery included a complete wet end rebuild with new OptiPress Linear technology. The project also featured dryer section modifications and a new finishing section. Advanced automation systems, including Valmet DNA process controls and quality measurement systems, enhance operational efficiency.

Sustainable Packaging Advancement

The PM2 startup represents significant progress in sustainable packaging production. The machine will continue ramping up production in coming months. Both organizations remain committed to advancing high-quality, environmentally responsible packaging solutions.

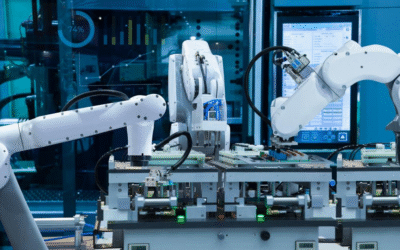

Industrial Automation Applications

Valmet’s automation solutions provide real-time process monitoring and control capabilities. The integrated systems enable predictive maintenance and quality optimization. Furthermore, they support data-driven decision making throughout the manufacturing process.

Expert Commentary: Industry Transformation

The packaging industry increasingly demands sustainable solutions and advanced automation. Successful projects like PM2 demonstrate how traditional paper manufacturers can pivot effectively. Companies investing in modern automation technologies gain competitive advantages through improved efficiency and product quality.

Implementation Scenario: Automated Quality Control

The new quality measurement system continuously monitors board specifications. This automation reduces manual inspections while improving consistency. Consequently, manufacturers achieve higher product quality with reduced operational costs.

Frequently Asked Questions

What is solid bleached sulphate (SBS) board used for?

SBS board serves premium packaging applications requiring high quality and durability. Common uses include cosmetic packaging, pharmaceutical containers, and luxury consumer goods.

How does Valmet’s automation technology benefit paper manufacturers?

The technology provides comprehensive process control and real-time data analytics. This enables optimized production, reduced waste, and consistent quality output.

What challenges do paper machine rebuilds typically face?

Major challenges include maintaining production schedules, managing supply chain complexities, and ensuring minimal disruption to existing operations during implementation.

How does automation support sustainable manufacturing?

Advanced control systems optimize energy consumption and raw material usage. They also minimize waste through precise process management and predictive maintenance.

What factors make packaging grades strategically important?

Growing e-commerce and sustainable packaging demands drive market expansion. Packaging grades often offer better margins and growth potential compared to traditional paper products.

LEAVE A COMMENT