VDA 5050 AMR Integration Solutions

Open Standards Revolutionize Industrial Automation: Bosch Rexroth and SYNAOS Demonstrate VDA 5050 Integration

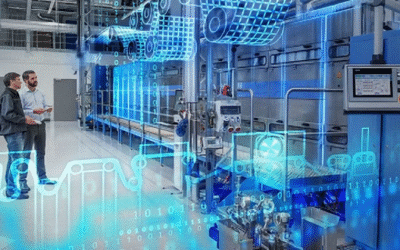

October 8, 2025 – Bosch Rexroth has partnered with SYNAOS, an expert in intelligent material flow orchestration, to successfully integrate K.Hartwall’s autonomous mobile robot (AMR), the A-MATE Lite, into the SYNAOS Intralogistics Platform. The vehicle utilizes Bosch Rexroth’s VDA 5050-compliant ROKIT software and is now operational in production environments. This collaboration highlights how open standards enable flexible and scalable automation for mixed equipment fleets.

The Challenge of Diverse Automation Systems

Manufacturers face increasing complexity with multiple autonomous vehicle types and vendors. Integrating different systems into existing workflows requires vendor-neutral solutions. Moreover, coordinating mixed fleets and ensuring seamless communication demand standardized approaches. The VDA 5050 standard addresses these industrial automation challenges directly.

VDA 5050: The Universal Language for Mobile Robots

The VDA 5050 communication standard serves as a critical bridge between mobile robots and fleet management systems. Bosch Rexroth’s ROKIT Navigator enables seamless communication across different manufacturer platforms. Integrated with the A-MATE Lite, it ensures complete VDA 5050 compatibility. Combined with ROKIT Locator positioning software, the system creates intelligent, flexible automation components.

Practical Benefits of Open Architecture Systems

The ROKIT software’s alignment with open interfaces enables straightforward vehicle integration. The onboarding process required minimal time, demonstrating how standards reduce implementation complexity. “Our ROKIT solutions provide robust, open systems that dramatically lower integration challenges,” stated Jörg Heckel, Head of Project Robotics at Bosch Rexroth.

Industry Impact and Operational Advantages

Open systems deliver significant benefits across the automation ecosystem. Operators gain flexibility to combine vehicles from multiple manufacturers. Equipment manufacturers using modular components accelerate development cycles. Fleet management system providers experience substantially reduced integration timelines. The ACTIVE Shuttle from Rexroth demonstrates similar integration capabilities.

Expert Perspective on Future Automation

“Our mission involves making intralogistics operations efficient and future-proof,” explained Dr. Philipp Schäfers of SYNAOS. “The rapid A-MATE Lite integration showcases the power of open standards. This modular approach represents a fundamental shift for industrial automation and control systems.”

Collaborative Success in Automation Innovation

This project’s achievement stems from close cooperation between Bosch Rexroth, SYNAOS, and K.Hartwall. The integration exemplifies the potential of standardized, modular technologies when industry leaders combine their expertise in practical automation solutions.

Live Demonstration Opportunities

Visitors can experience this collaborative automation solution at the Mobile Robotics Summit in Düsseldorf. The live demonstration provides exclusive insights into how open standards create more adaptable and future-ready automation systems for industrial applications.

Implementation Case Study: Automotive Parts Distribution

A European automotive distributor implemented this integrated AMR solution across their warehouse operations. The result was a 40% reduction in integration costs compared to proprietary systems. Furthermore, they achieved 30% faster deployment times and gained the flexibility to mix AMR brands according to specific operational needs.

Frequently Asked Questions

What is VDA 5050 and why is it important?

VDA 5050 is an open communication standard that enables different AMR brands to work together seamlessly within the same fleet management system.

How does ROKIT software benefit equipment manufacturers?

ROKIT provides pre-certified VDA 5050 compliance, reducing development time and ensuring interoperability with major fleet management systems.

What types of autonomous vehicles can use this integration?

The system supports various AMRs including the A-MATE Lite, ACTIVE Shuttle, and other VDA 5050-compliant vehicles from multiple manufacturers.

How long does typical integration take?

Projects using standardized components typically require significantly less time than proprietary solutions, often completing in weeks rather than months.

What are the cost benefits of open standards?

Open standards reduce vendor lock-in, lower integration expenses, and provide long-term flexibility for expanding or modifying automation systems.

LEAVE A COMMENT