Virtual PLCs Transform Industrial Control

The Evolution of Virtual PLCs: From Hardware to Cloud-Based Control

Understanding Programmable Logic Controllers

Programmable Logic Controllers process signals to control industrial machinery. They connect to sensors, actuators, and human-machine interfaces. Traditional PLCs combine hardware and software in integrated packages.

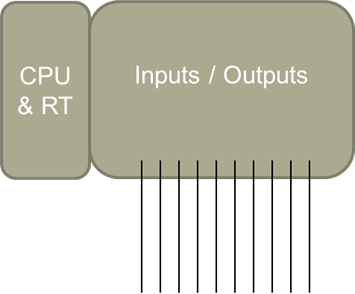

Traditional Hardware PLCs

Classical PLCs represent the foundation of industrial automation. These compact devices feature proprietary hardware and interfaces. Their runtime systems integrate directly with physical components.

Figure 1: Architecture of hard/classical PLC.

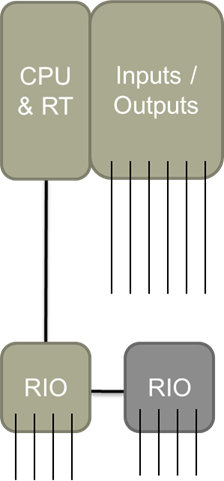

Remote I/O Systems

Remote I/O technology separated sensor interfaces from central controllers. This advancement enabled longer distance connections and space optimization. Standardized fieldbus systems made multivendor compatibility possible.

Figure 2: Architecture of PLC and RIO.

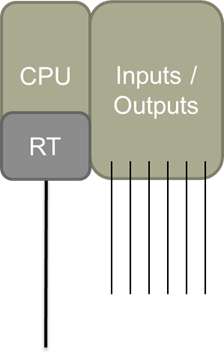

Soft PLC Revolution

Soft PLCs decoupled runtime software from specific hardware platforms. This flexibility allowed deployment across different processors and operating systems. The technology emerged alongside remote I/O during the 1990s.

Figure 3: Architecture of a soft PLC.

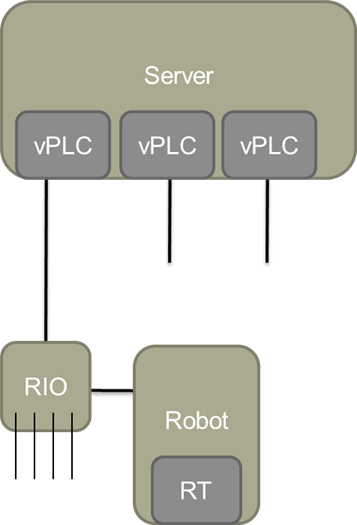

Virtual PLC Technology

Virtual PLCs represent the latest evolution in control systems. They separate runtime environments from physical inputs and outputs. Container and hypervisor technologies enable this virtualization approach.

Implementation Architecture

Virtual PLC deployment progresses through multiple stages. It begins with onsite servers, advances to private clouds, and eventually reaches public cloud platforms. Critical real-time functions may remain locally deployed.

Figure 5: Several vPLCs running on a server.

Key Benefits and Advantages

Virtual PLC technology offers significant operational improvements:

- Enhanced application development flexibility

- Reduced hardware costs and variety requirements

- Lower maintenance and energy consumption expenses

- Improved scalability throughout equipment lifecycle

- Centralized management capabilities

Industry Implementation Examples

Volkswagen’s Audi division pioneered virtual PLC implementation. Their Neckarsulm factory operates axle assembly lines using Siemens S7-1500V virtual PLCs. This system has been operational since January 2024.

Commercial Virtual PLC Products

Multiple vendors now offer virtual PLC solutions:

- Beckhoff: TwinCAT for Linux

- CODESYS: Virtual Control SL

- Siemens: SIMATIC S7-1500V

- Phoenix Contact: Virtual PLCnext Control

Technical Requirements and Challenges

Virtual PLCs demand robust communication networks. They must maintain quality of service across greater distances. Security concerns increase with cloud-based implementations.

Performance Considerations

Cycle times remain critical for all PLC types. Virtual PLCs currently support cycles down to 10ms for onsite deployment. More demanding applications still require traditional hardware solutions.

Standardization Efforts

Global standardization initiatives address virtual PLC requirements. The IEC/IEEE 60802 TSN profile supports industrial automation needs. Chinese standards organizations also contribute to architecture development.

Future Outlook

Hard, soft and virtual PLCs will continue coexisting. Selection depends on specific application requirements and performance needs. The technology continues evolving toward greater flexibility and cloud integration.

Expert Analysis

Virtual PLCs represent a fundamental shift in industrial control architecture. They enable new business models like control-as-a-service. However, responsibility distribution among multiple vendors presents ongoing challenges.

Practical Application Scenario

A manufacturing plant implementing virtual PLCs could reduce hardware costs by 30%. Centralized management might cut maintenance time by 40%. The flexibility supports rapid production line reconfiguration.

Frequently Asked Questions

What distinguishes virtual PLCs from traditional PLCs?

Virtual PLCs separate control runtime from physical hardware. They utilize containerization instead of dedicated processors.

Can virtual PLCs handle safety-critical applications?

Yes, solutions like CODESYS Virtual Safe Control SL address safety requirements. However, critical functions often remain locally deployed.

What communication protocols support virtual PLCs?

PROFINET, EtherCAT, and OPC UA provide foundation protocols. Time-Sensitive Networking enables deterministic performance.

How do cycle times compare between PLC types?

Traditional PLCs achieve sub-millisecond cycles. Virtual PLCs currently support 10ms cycles for onsite deployment.

What industries benefit most from virtual PLCs?

Discrete manufacturing and process industries see significant benefits. Applications requiring flexibility gain particular advantage.

LEAVE A COMMENT