Virtual Twin Solutions for Manufacturing Strategy

Virtual Twin Technology Transforms Manufacturing Challenges Into Competitive Opportunities

Strategic Response to Global Trade Pressures

Manufacturers face increasing pressure from international tariffs and trade uncertainties. Companies must evaluate significant capital investments for new facilities or expansions. The fundamental question becomes: What investment requirements exist for building or expanding manufacturing capacity?

Virtual Twin Technology Overview

Virtual twin solutions provide comprehensive digital modeling of production systems. These advanced simulations enable accurate evaluation of facility designs and manufacturing processes. DELMIA Industrial Engineering software integrates existing digital assets including drawings, CAD models, and bills of material. The platform transforms these elements into dynamic three-dimensional factory replicas.

Operational Visualization Benefits

Teams can conduct virtual factory walkthroughs before physical construction begins. The technology allows testing of different layouts and observing material flows. This identifies potential inefficiencies in space utilization, timing, and energy consumption. Companies can address these issues proactively, reducing operational waste and equipment downtime.

Comprehensive Implementation Framework

Data Consolidation Phase

Combine 2D drawings, CAD models, and point-cloud scans into a unified platform. This creates a single source of truth for equipment, layout, and process information.

Process Engineering Development

Convert engineering BOM to manufacturing BOM, sequence operations, and assign resources. Generate work instructions while linking product and process before financial commitment.

Machining and Additive Manufacturing

Simulate NC toolpaths and additive layers directly within the virtual environment. Validate surface quality and spindle loads while maintaining design synchronization.

Factory Layout Optimization

Configure machines, conveyors, and aisles in three-dimensional space. Conduct flow simulations to evaluate throughput, buffer capacities, and shift patterns while identifying constraints.

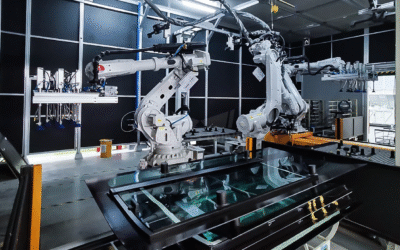

Robotics and Automation Integration

Incorporate extensive robot libraries, generate collision-free paths, and optimize cycle parameters. Ensure automation configurations meet production requirements without excessive investment.

Ergonomics and Safety Validation

Assess manual task requirements including reach, posture, and load handling. Verify safe operational clearances between personnel, robots, and automated guided vehicles.

Virtual Commissioning Process

Integrate actual PLC and robot programming into the digital model. Debug control logic and train operational staff within the virtual environment, reducing onsite commissioning duration.

Continuous Improvement Cycle

Stream manufacturing execution and IoT data back into the virtual twin. Monitor overall equipment effectiveness and conduct scenario analysis as market conditions evolve.

Strategic Business Advantages

This comprehensive approach transforms disconnected engineering data into actionable operational intelligence. Organizations achieve multiple strategic benefits before committing to physical investments. Companies can evaluate future plant performance while identifying potential inefficiencies. The technology enables rapid testing of tariff, labor cost, and logistics scenarios. Manufacturers can optimize product, process, and personnel configurations for maximum operational effectiveness.

Frequently Asked Questions

What is a virtual twin in manufacturing?

A virtual twin is a comprehensive digital replica of manufacturing facilities and processes that enables simulation and optimization before physical implementation.

How do virtual twins reduce investment risk?

They identify inefficiencies and operational constraints during planning phases, allowing corrections before capital commitment and physical construction.

What types of scenarios can virtual twins simulate?

The technology can model tariff impacts, labor cost variations, logistics changes, production bottlenecks, and equipment performance under different conditions.

How does virtual commissioning differ from traditional methods?

Virtual commissioning uses digital models to test control systems and train personnel, significantly reducing onsite debugging time and operational disruptions.

Can virtual twins be used after facility implementation?

Yes, continuous data streaming from operational systems enables ongoing optimization and scenario analysis as production requirements evolve.

Implementation Guidance

Successful virtual twin deployment requires systematic data integration and cross-functional collaboration. Begin with comprehensive asset digitization and progress through phased implementation. The technology transforms capital investment decisions from speculative ventures into data-driven strategic initiatives, providing manufacturers with significant competitive advantages in volatile global markets.

LEAVE A COMMENT