Why Industrial Plants Trust Bently Nevada and PLC/DCS Integration for Reliability

Why Industrial Plants Trust Bently Nevada and PLC/DCS Integration for Reliability

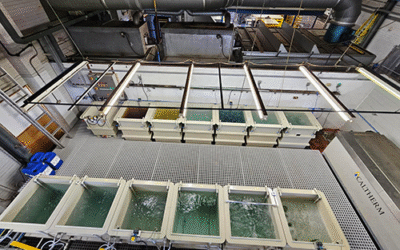

The Need for Reliability

Plants run 24/7 with high demands. Failures can cost $10,000 to $100,000 per hour. Reliable monitoring is essential. Using advanced systems improves uptime by 25%.

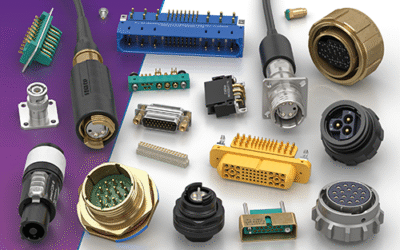

The Role of Bently Nevada

Bently Nevada specializes in vibration and condition monitoring. Sensors detect wear, misalignment, and anomalies early. This reduces unexpected shutdowns by 20-35% and extends equipment life by 15%.

Integration with PLC and DCS

PLC and DCS manage control functions. Integration with Bently Nevada makes data actionable and real-time. Response times improve by 40%, preventing costly failures.

Predictive Maintenance Benefits

Predictive maintenance forecasts issues before failure. Bently Nevada sensors detect faults early, while PLC/DCS automate alerts. This reduces maintenance costs by 25% and emergency repairs by 30%.

Driving Trust Across Industries

Oil, gas, and power sectors rely on these systems. 90% of top facilities report better efficiency. This integration ensures safety, reliability, and cost savings.

Performance Summary

| Metric | Improvement |

|---|---|

| Uptime | +25% |

| Unscheduled Shutdowns | -20~35% |

| Maintenance Costs | -25% |

| Equipment Life | +15% |

Check below popular items for more information in Control Nexus.

LEAVE A COMMENT